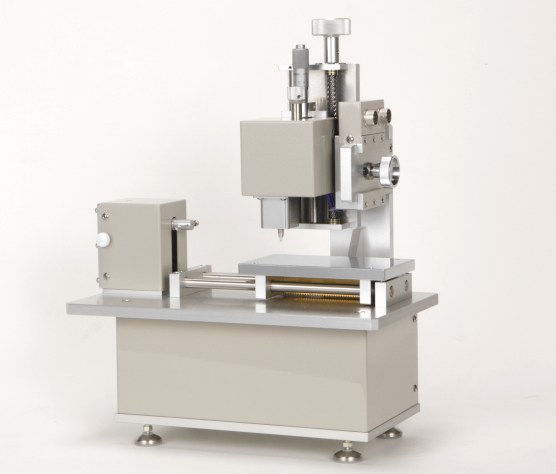

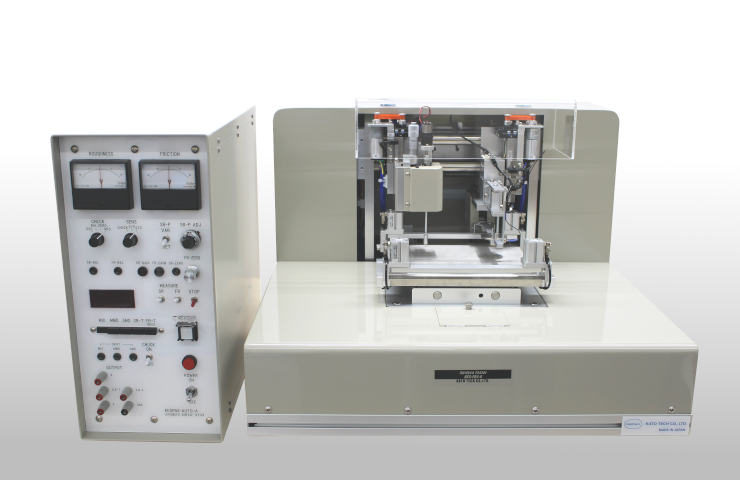

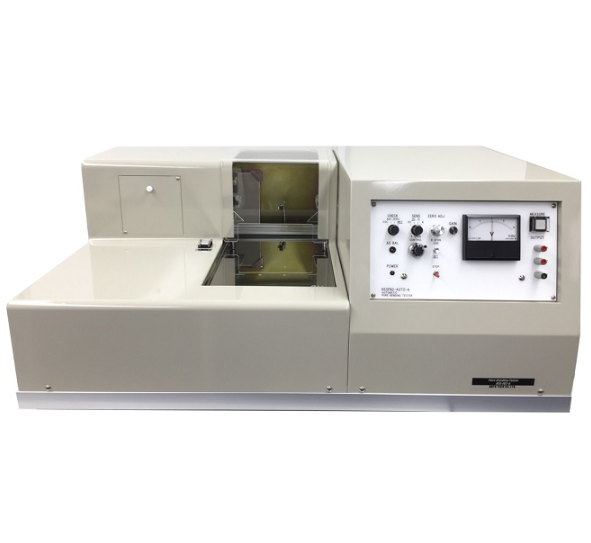

Adhesion Tester

The adhesion tester is a device specifically used to detect the strength of the adhesion of materials. The following is a detailed description of its main uses, compliance standards, and technical parameters:

I. Main Uses

The adhesion tester has extensive application value in multiple fields, including but not limited to: - **Medical Field**: It is used to evaluate the adhesion performance of medical products such as medical gels, dressings, and patches, ensuring that they can stably adhere to the skin in practical applications and exert therapeutic effects. - **Cosmetics and Skin - care Industry**: It tests the adhesion of cosmetic gel products, facial masks, eye creams, etc., to ensure that they can closely fit the skin during use and enhance the product's effectiveness. - **Food Manufacturing Industry**: It is used to detect the adhesion performance of food - grade gels, packaging materials, etc., ensuring their stability during food processing, packaging, and transportation. - **Adhesive Industry**: It tests the adhesion of various adhesives, adhesive tapes, labels, etc., to evaluate their quality and performance. - **Materials Science Field**: It studies the adhesion performance of materials, providing basic data support for material development and application.

II. Compliance Standards

- Specific standards for different test objects, such as the adhesion test standards for medical gels, cosmetics and skin - care products, food packaging materials, etc. - General standards in the adhesive industry, such as GB/T 2792 *Test Method for 180°Peeling Strength of Pressure - Sensitive Adhesive Tapes*, ASTM D3330 *Standard Test Method for Peel Adhesion of Pressure - Sensitive Tape*, etc. These standards specify in detail the test methods for the adhesion tester, specimen preparation, test conditions, etc., providing a unified standard for the use of the tester.

III. Technical Parameters

- **Measurement Range**: Usually covering 0 - 30000mN or wider to adapt to the testing needs of different materials. Some devices may have a smaller measurement range, such as 0.01N - 100N, which is suitable for measuring materials with relatively low adhesion. - **Measurement Accuracy**: Generally grade 0.5 or higher to ensure the accuracy of test results. - **Stroke**: Usually 650mm or longer to meet the requirements of different specimen sizes and test methods. - **Pressing Roller Mass**: Usually 2000g±50g, used to apply a certain pressure to the specimen to ensure a tight adhesion between the specimen and the test plate. - **Test Speed**: The adjustable range is generally 1 - 500mm/min (stepless speed regulation) to simulate different peeling speeds. Some devices may have a wider speed - adjustment range. - **External Dimensions**: Usually about 880mm (length) × 320mm (width) × 400mm (height), facilitating placement and movement. The dimensions of devices from different brands and models may vary. - **Power Supply**: Usually AC 220V 50Hz to ensure the normal operation of the tester. Some devices may support other voltages and frequencies.

Leave Message Get Price