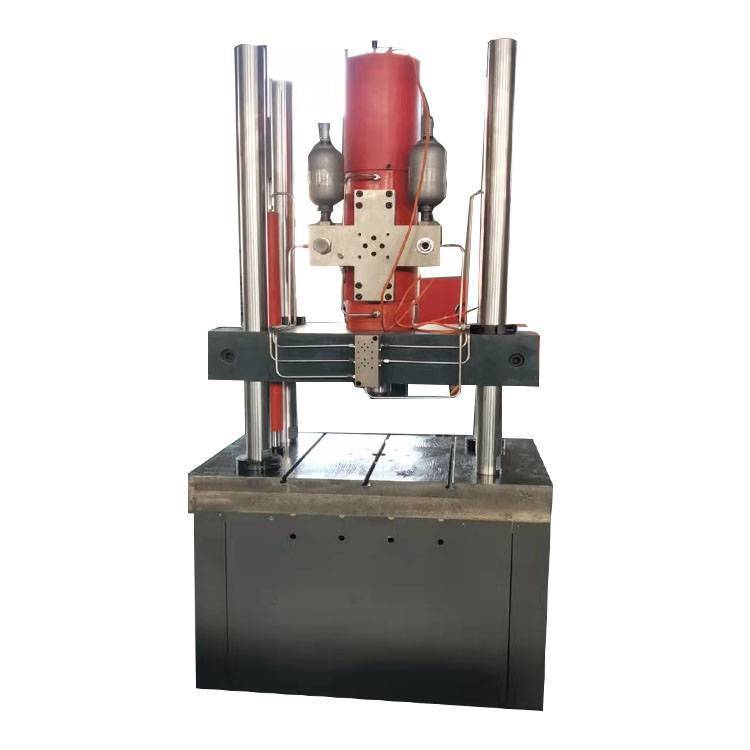

SAE J2380 Compliant Seat Frame Strength Validation System

Applicable standards:

The National Standard of the People's Republic of China (GB) : such as GB 15083, this standard specifies the strength requirements and test methods of the car seat system, which is applicable to the seats and their fixtures of M and N cars.

Federal Motor Vehicle Safety Standard (FMVSS) : such as FMVSS 207, this standard specifies the strength requirements of the seat back and its adjustment device and applies to all seats in Class M1 vehicles.

Economic Commission for Europe Regulation (ECE R) : such as ECE R17, this regulation regulates the strength of car seats, seat belt anchors, etc.

Main parameters:

Loading capacity: The test bench should have sufficient loading capacity to simulate the various loads that the seat may withstand in actual use. For example, for a 20g static loading test, the test bench needs to be able to apply a force equivalent to 20 times the gravity of the seat assembly.

Loading method: The test bench should support a variety of loading methods, such as horizontal forward, horizontal backward, torsion, etc., to meet the needs of different test projects.

Test accuracy: The loading accuracy and measurement accuracy of the test bench should meet the requirements of the relevant standards to ensure the accuracy and reliability of the test results.

Number of tests: The test bench should have the function of setting and recording the number of tests for durability testing.

Control mode: The test bench is usually controlled by computer servo to achieve accurate loading and measurement.

Data acquisition and processing: The test bench should be equipped with a data acquisition system, which can automatically record various data during the test process and generate test reports.

Leave Message Get Price