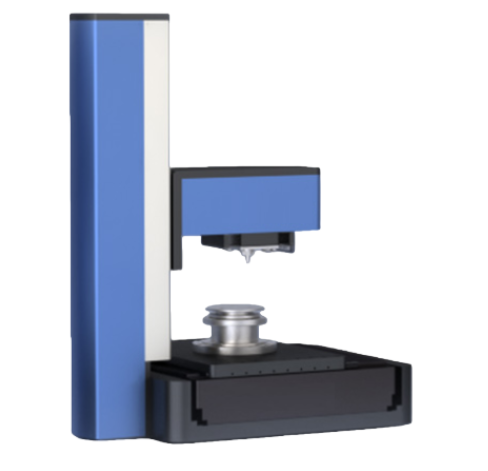

Din Abrasion Resistance Tester

The Main Purpose:

Din abrasion resistance tester for rubber is mainly used for the abrasion resistance detection of an elastic material, conveyor belts, rubber, tires, shoe soles, synthetic leather and other soft materials.

Standard:

DIN 53516, JIS K6369 ,GB/T 20991,GB 20265-2006,GB20266-2006,SATRA TM174,BS 903,JIS K6264,GB/T9867,ISO4649

Test procedure:

1)According to the method of measuring the proportion of materials, we measure the proportion of materials which is indicated as Q.

2)Adding 250g and 500g weight to the upper end of the fixed column,we must make sure that the total weight of the fixed column is 1kg (specimen clamp itself weighs 250g)

3)The specimen should be cleaned with soft bristles, in order to keep any dirt away, please wipe the burrs with fingers.

4)Using electronic scales to weigh the specimen, the numerical value should be accurate to 0.001g, which is indicated as W1.

5)Clean the dirt left by previous two test with the soft bristles.

6)Fix the test piece, and the surface of the specimen should be parallel to the bottom of the stationary column. And then turn the knob anticlockwise for two revolutions, which make the surface of the specimen can be higher than the column head 2.0±0.2mm.

During the testing process, if the test piece is expected to wear poorly, the machine has to stop halfway when the wears may exceed 2mm, and we should pull out the specimen 2mm so that we can continue the test.

7)Lower the column head and place on the starting point of the drum wheel, and then start the machine and vacuum cleaner. Let the specimen be worn on the drum wheel at from the starting point to terminal point, which whole distance is 40m.

8)Remove the specimen from the column head, wipe the adhesive fragment with our finger and remove dirt and debris with the soft brush.

9)Weigh the specimen again and the numerical value should be accurate to 0.001g, which is indicated as W2.

Din Rubber Abrasion Tester Test result:

To calculate and indicate the mean of three test results, which should be corrected to millimeter.

If you want to download the standard pdf for free, please contact us with comment, we will respond to you as soon as possible.

Leave Message Get Price