An Overview Of Meltblown Nonwoven Process

Meltblown nonwoven fabrics are still in the early growth stage. They are already becoming more and more popular in the medical and filter industries due to the meltblown ability to produce microfibers.

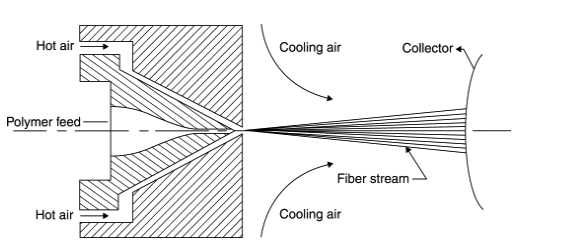

The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments, integrated with the conversion of the filaments into a random laid nonwoven fabric.

First developments in this field of technology in the industrial area started around 1945. The general process description is similar to the spunlaid process, but in detail, both types of processes are quite different. Using the melt blown technology, the spun filaments are accelerated by means of hot, fast-flowing air that is directly blown onto a moving substrate, creating a self-bonded web.

The meltblown process directly transforms polymer resins to a nonwoven fabric in a single, integrated process. The process was originally developed by the Research Laboratories .The final meltblown fabric properties are determined by the polymer resin, conditions in the extruder, ambient air conditions, the bonding method and the finishing treatment, among other process parameters.

The output of the meltblown process is a microfiber with diameters ranging from as little as 0.1 micron to as large as 15 microns.

2020-04-13 17:20