Site: Home > News and events

What Factors Affecting Flame Resistance

Flammability is the ability to burn or ignite any substance by means of fire or any kind of combustion. Various test procedures exist to determine the flammability. In domestic sphere many serious and tragic accidents are the results of clothing catching fire.Flameproof fabrics are absolutely necessary for protective clothing in many industrial processes where chances of inflammable fabrics being ignited are high.

Fibre content, fabric construction, fabric weight and fabric finishes can all affect the flammability or rate of burn of textiles. All textiles will burn to varying degrees if exposed long enough to a flame or an intense heat source. When discussing any one factor below, it is assumed that all other pertinent factors remain constant.

Fibre Content:With regards to flammability, fabrics may be classified generally according to fibre content:Readily flammable:In general, these fibres ignite readily and burn rapidly, leaving a light ash residue (e.g., cotton, acetate, triacetate, rayon, ramie and marabou).

Moderately flammable:These fibres are more difficult to ignite. The synthetics tend to melt and drip, sometimes self-extinguishing upon removal of the ignition source (e.g., acrylic, nylon, polyester, olefin, and silk).

Relatively nonflammable:In general, these fibres will not support combustion after removal of the ignition source (e.g., wool, modacrylic, vinyon, and Saran).

Blends:Fabrics made of two or more fibres (blends) display flammability characteristics that are different from those of the individual fibres, and testing is the only way to ascertain the flammability of the blend. For example, although polyester is less flammable than cotton, some cotton/polyester blends have been shown to burn rapidly and generate more heat than 100% cotton fabrics. This is due to a "scaffolding" effect, where the charred cotton in the blend acts as a support or scaffold for the polyester fibres. The melting polyester in the blend does not drip away as it may do in 100% polyester fabrics, and continues to burn.

Blended fleece fabrics such as 80% cotton/20% polyester may burn quickly like 100% cotton fleece because the brushed surface can be 100% cotton, while the base may be a blend of 50% cotton/50% polyester or 60% cotton/40% polyester. A flame can quickly pass over the raised surface of the fleece, igniting the readily flammable cotton. Once the base of the fabric is ignited, the moderately flammable polyester slows down the rate of burn to one somewhat slower than that of a pure cotton fabric of equal weight and construction.

Fabric Construction:For textiles, the critical factor in determining flammability ratings for varying construction techniques is the availability of oxygen. Combustion is accelerated if air can permeate a fabric easily. The more loosely woven a fabric, the more combustible it is, and the faster the flame will travel over the surface of the fabric. For example, a lightweight tightly woven polyester fabric may be difficult to ignite, whereas a lightweight loosely woven (mesh) polyester fabric may fail flammability testing.

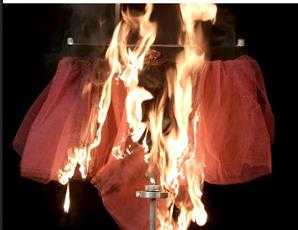

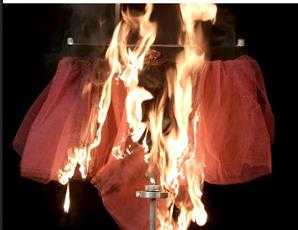

Fabrics with a raised fibre surface require special consideration. Fleece-style fabrics, flannelettes and terry towelling are some examples of construction which allow individual fibres or yarns to be exposed readily to accidental contact with ignition sources. This, combined with the fact that air readily penetrates and circulates around these loose fibres and yarns, increases the hazard level of raised fibre surface fabrics.

The flammability hazard with raised fibre surface fabrics involves the phenomenon called "surface flash" whereby a flame can travel rapidly over the fabric surface, singeing the fibre ends. This flash, in itself, may not be dangerous unless the intensity of the flame is sufficient to ignite the base fabric. In testing, this is known as timed surface flash with base burn.

Fabric Weight:A lightweight fabric tends to be more flammable than a heavier weight fabric of the same fibre content and fabric construction. For example, rayon chiffon usually fails to meet the flammability requirements while rayon georgette generally passes. The georgette yarns are more tightly twisted and the weave is more tightly compacted than chiffon. Consequently, the georgette fabric is more difficult to ignite, and when it does ignite, the rate of burn is slower because of the restricted availability of oxygen.

Fabric Finishes:A chemical or mechanical finish alters the surface of a fabric and in doing so affects the flammability of that fabric. Finishes not designed specifically to retard flammability must be considered as unknown variables that influence the total flammability of the textile product. Only through testing can the effect of the system be ascertained. For example, enzyme washes designed to reduce the pile on 100% cotton fleece tend to reduce the surface flash by shortening and compacting the loose cotton fibres.

2019-11-08 10:32