Site: Home > News and events

A STUDY ABOUT DYNAMIC SEAM FATIGUE OF DENIM FABRICS

In apparel production, the sewing process is one of the critical processes in the determination of productivity and the quality of the finished garment. Consistency of sewing quality is essential if the apparel manufacturer is to satisfy the customer. Failings or variations in sewing quality may be caused by one or both of the following factors:mechanical factor (the sewing machine) and human factor (the operator) [1].

Performance characteristics of seam like; seam strength, seam opening and seam damage besides performance characteristics of fabrics should be investigated to evaluate clothing performance. The expected performance value of a textile product varies depending on the field of use of products. Research and development (R&D) works on parameters such as structural features of the products, the raw materials and the physical or chemical processes are required [2].

When the seam, which is defined as joining of two or more fabrics by means of one or more rows of stitches, is exposed to transverse strain, a displacement (seam slippage) of the stitch can occur. According to some results from experimental investigations, the amount of seam opening mainly depends on the fabric structure, the character of yarn systems in the fabric,the seam type, the stitch density and the sewing-thread tension [3].

Lomov (1998) proposed a mathematical model of a woven fabric deformation during an interaction with a needle and to compute the penetration force as a function of warp and weft mechanical properties, weave pattern [4].

Hui and et all (2007) investigated the use of artificial neural networks (ANN) to predict the sewing performance of fabrics. The purpose of this study is to verify the ANN techniques that could be emulated as human decision in the prediction of sewing performance of fabrics.After 10,000 iterations of training of backpropagation (BP) neural network, the neural network converged to the minimum error level. The experimental results reveal the great potential of the proposed approach in predicting the sewing performance of fabrics for apparel production.

Haghighat and et all (2014) investigated the sewability of the woven denim fabrics based on needle penetration force (NPF). Measurement of NPF was performed on an Instron 5566 Tensile Tester. The statistical analysis results show that NPF is influenced by these parameters. Fabric weight has a greater effect on NPF than other parameters. With increasing fabric weight, number of fabric layers, and needle size, the NPF increases. The trend of this increase is nonlinear as predicted by a cubic regression equation. The fabric sewability is also influenced by the mentioned parameters. The fabric sewability becomes poor with increasing fabric weight, needle size, and number of fabric layers. Generally, lighter fabrics sewn with finer needles have better sewability [5].

Shimazaki and Lloyd (1990) analyzed the opening behavior of lockstitch seams under cyclic loading conditions, using models of the slippage of yarns in the fabric and the deformation of the stitch itself. The extension properties of the sewing thread under constant cyclic loading conditions were included by using an empirical formula to predict the maximum strain in terms of the applied load and its number of repetitions. Similarly, an empirical formula was used to predict the amount of yarn slippage in woven fabric, in terms of the applied load and its number of repetitions. This formula was obtained from experiments in which the sewing threads in a lockstitch seam were replaced by pins. These results were combined to provide a method for predicting the deformation of a stitch under cyclic loading conditions. The amount of seam opening actually occurring was measured experimentally under different conditions and compared with the calculated values [6].

EXPERIMENTAL

Materials

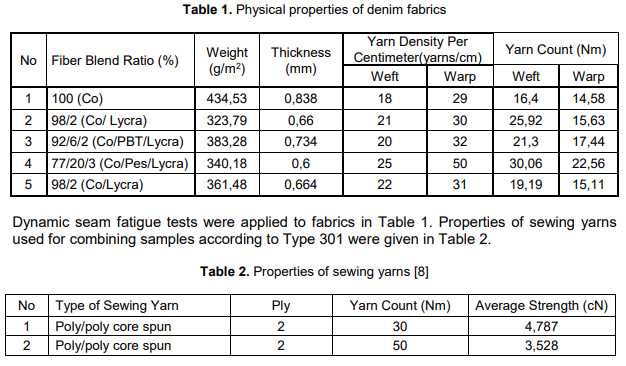

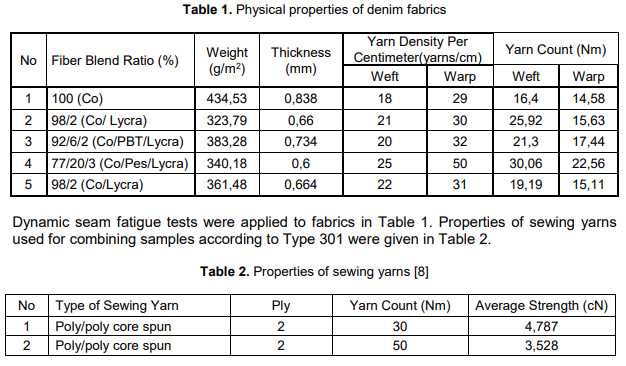

In this study, denim fabrics which have 3/1 Z twill weave structure and different fiber blend ratios were used. Physical properties of denim fabrics are given in Table 1.

Method

The determination of seam openings with dynamic seam fatigue tests; were performed using dynamic seam fatigue tester according to ASTM D4033-92 Standard Test Method for Resistance to Yarn Slippage at the Sewn Seam in Upholstery Fabrics.

Two parts of fabric which have 190 x 255 mm dimensions for one fabric were cut for dynamic seam fatigue tests. When warp yarns of both of these parts were parallel to the edge of the 255 mm, they were sewn and referred to warp-warp samples. When weft yarns of both of these parts were parallel to the edge of the 255 mm, they were sewn and referred to weftweft samples. When warp yarns of one of these parts was parallel to the edge of the 255 mm and weft yarns of the other part was parallel to the edge of the 255 mm, they were sewn and referred to warp-weft samples. Three of warp-warp samples, three of weft-weft samples and three of warp-weft samples for each fabric were prepared.

The samples were sewn according to type 301 stitches with sewing needle 90 numbers as fineness. Stitch density was adjusted to be 7,5 stitches/inch for each sample. Polyester core spun sewing yarn 30 Nm as upper yarn, 50 Nm as lower yarn were used. Sewn samples were placed in montage boxes having a flexible polyurethane foam composite in. Center line of the seam was placed to be parallel to the wheel and distance of them was 25 ± 3 mm.

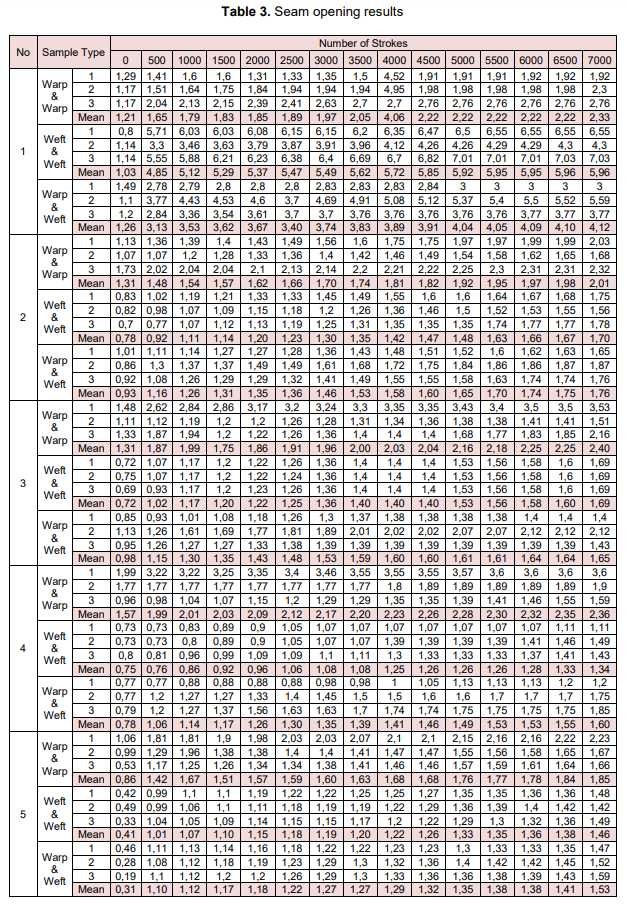

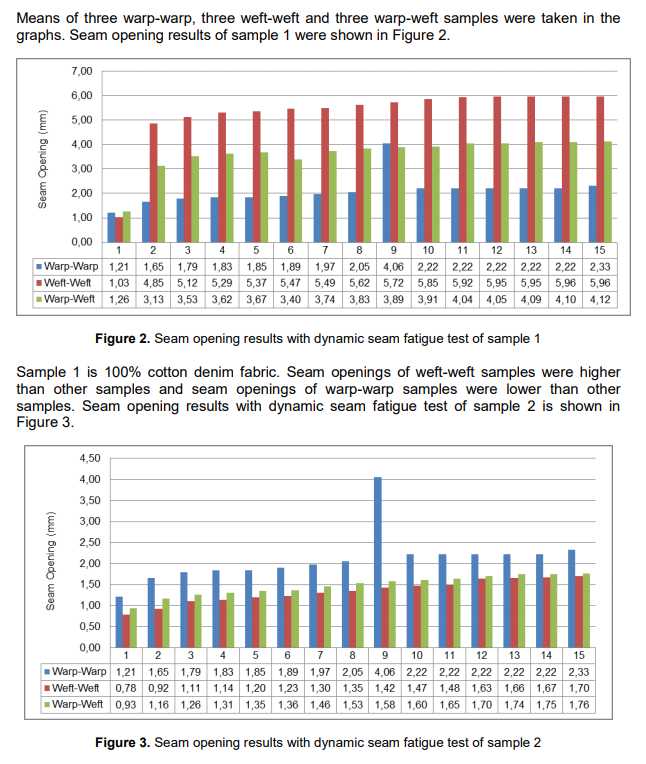

Rubber coated wheels fell on the samples from a fixed height. The frequency of the wheel was set to 25 ± 2 stroke/min. 7000 strokes were applied to each fabric. Before starting the periodic stroke, first measurements of seam openings were recorded from three warp-warp,three weft-weft and three warp-weft samples for one fabric. Dynamic seam fatigue tester was stopped at the end of every 500 strokes and seam openings occurred at the seam line were measured using a magnifying glass and a caliper. When 7000 strokes (7000 strokes/500 strokes = 14 measurements) completed, test was finished. 15 measurements including first measurement and 14 measurements were taken from each sample.

RESULTS and DISCUSSION

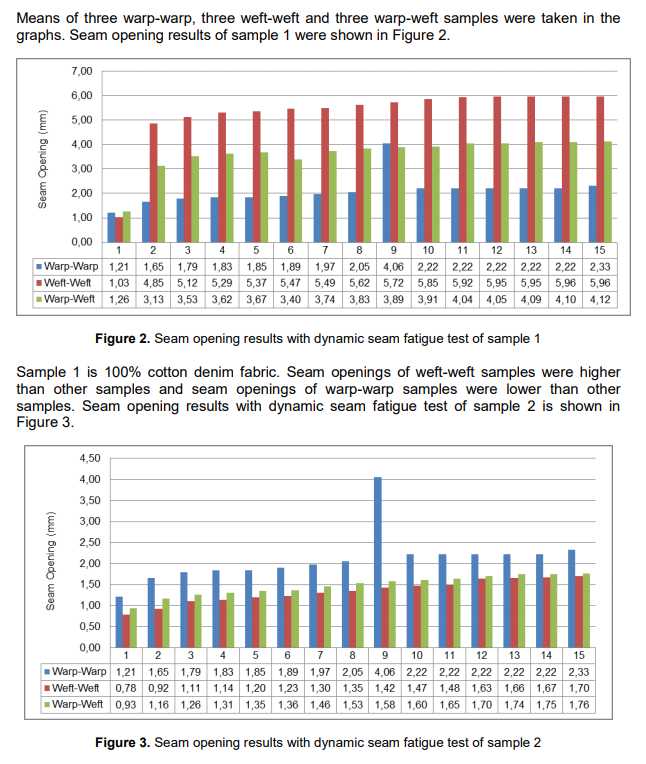

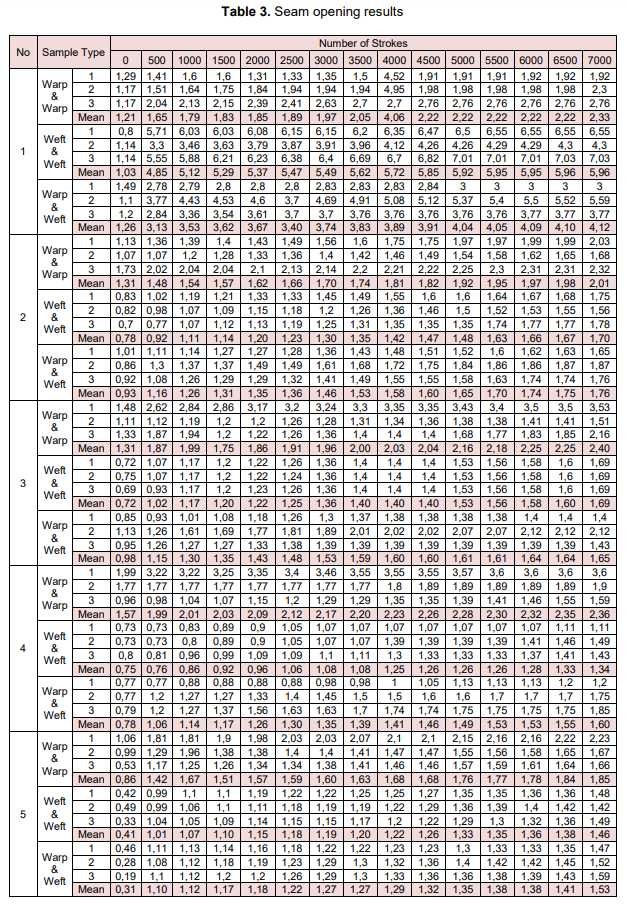

Seam opening on warp-warp, weft-weft and warp-weft samples were evaluated seperately for each fabric because of fabrics have different physical parameters. Seam opening results with dynamic seam fatigue test of samples were given in Table 3. As shown in Table 3, first nine measurements were taken before test was started. Second measurements were taken after 500 strokes. The other measurements were also taken in the same way at the end of every 500 strokes until 7000 strokes. In this way 15 measurements were obtained.

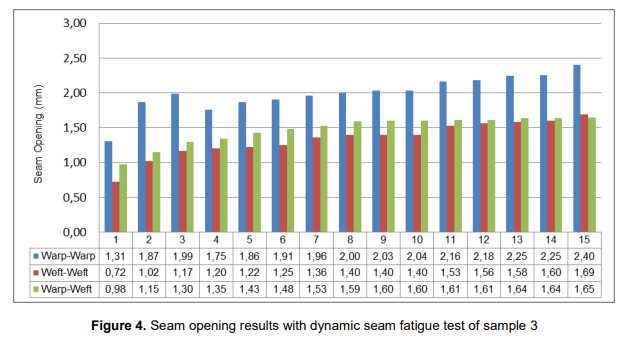

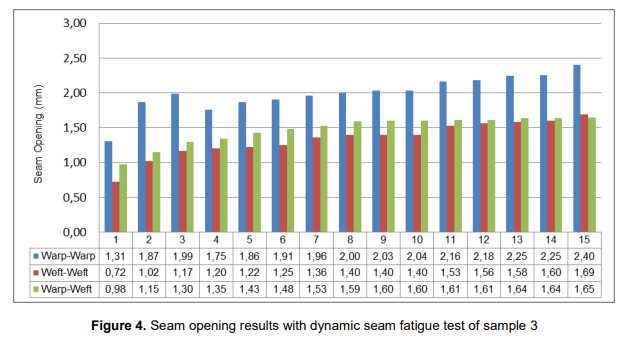

Sample 2 is denim fabric containing 98% cotton and 2% lycra. Seam openings of the warpwarp samples were higher than the weft-weft samples. It is said that amount of seam openings of samples decrases when fabric contains lycra in weft direction. Seam opening results with dynamic seam fatigue test of sample 3 is shown in Figure 4.

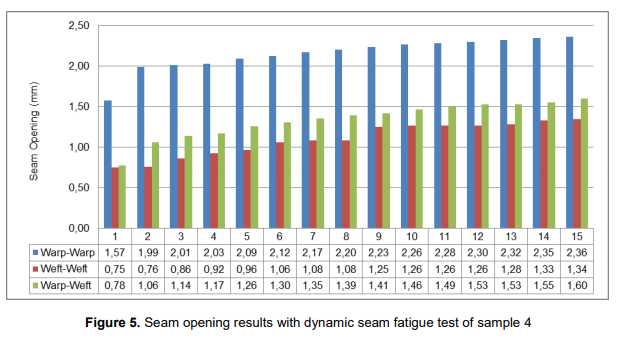

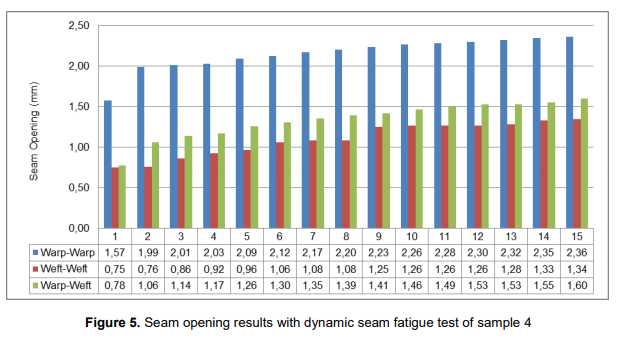

Sample 3 is denim fabric containing 92% cotton, 6% polybutylene terephthalate and 2% lycra. Seam opening of this sample is similar with sample 2. Seam opening in warp-warp samples in first 2000 strokes quickly realized. After 2500 strokes it is seen similar results with sample 2. Seam opening results with dynamic seam fatigue test of sample 4 is shown in Figure 5.

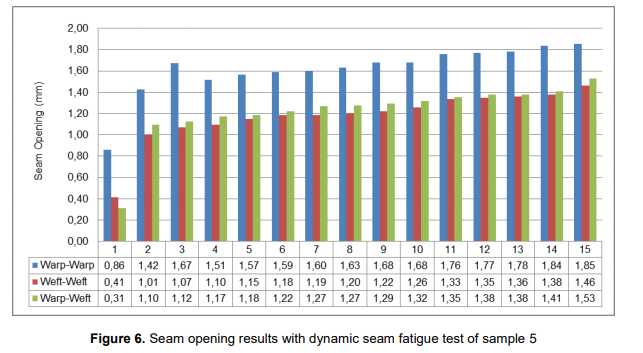

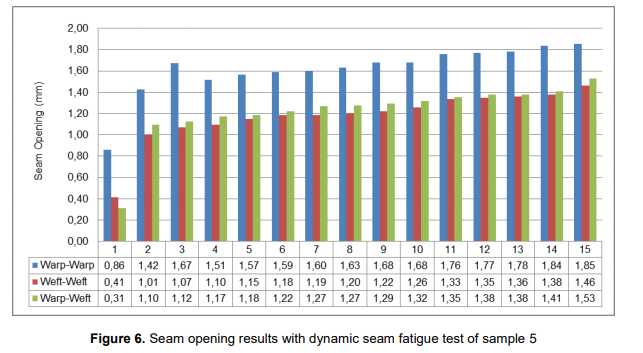

Sample 4 is denim fabric containing 77% cotton, 20% polyester and 3% lycra. Seam openings of sample 4 is the lowest. Seam opening results with dynamic seam fatigue test of sample 5 is shown in Figure 6.

Sample 5 is denim fabric containing 98% cotton and 2% lycra. Sample 5 has the lowest seam openings in all of samples. Fiber blend ratio of this sample is same with sample 2 but yarn density of this fabric is higher than sample 2. Reason of low seam opening of sample 5 can be explained with high yarn densities.

CONCLUSIONS

In this study, denim fabrics woven 3/1 Z twill with different constructions were performed dynamic seam fatigue tests. Seam opening on warp-warp, weft-weft and warp-weft samples were evaluated seperately for each fabric because fabrics have different physical parameters. Seam opening decrease when the fabric has lycra in weft direction. When lycra ratio in weft direction increase, the amount of seam openings decrease. Seam openings in the weft direction of 100% cotton fabrics is higher than the warp direction. Sample 5 has the lowest seam openings in all of samples. Fiber blend ratio of this sample is same with sample 2. When we compare them reason of low seam opening of sample 5 can be explained with high yarn densities.

2019-09-06 10:37