The method Glass Screen Wear Resistance Testing

Due to the property of being optically transparent, glass is widely used in a variety of products, such as windows, containers, optical lenses, mirrors and countless others. During the manufacturing process, glass can be formed into different shapes, ranging from flat sheets to highly intricate shapes,including fine glassware and optical fibers. Glass is very durable under most conditions; however, its brittle nature limits its application in certain applications.

In the last decade, the upsurge of smartphones has been tremendously propelling the development of novel glass lenses which possess superior mechanical properties, such as high hardness, great fracture toughness, and excellent scratch and wear resistance. A versatile instrument with the capacity of providing comprehensive testing on the above mechanical properties in an accurate and repeatable manner becomes vital for evaluation and comparison of the glass in Quality Control and Research and Development.

MEASUREMENT PRINCIPLE:

Nanoindentation is based on the standards for instrumented indentation, ASTM E2546 and ISO 14577.

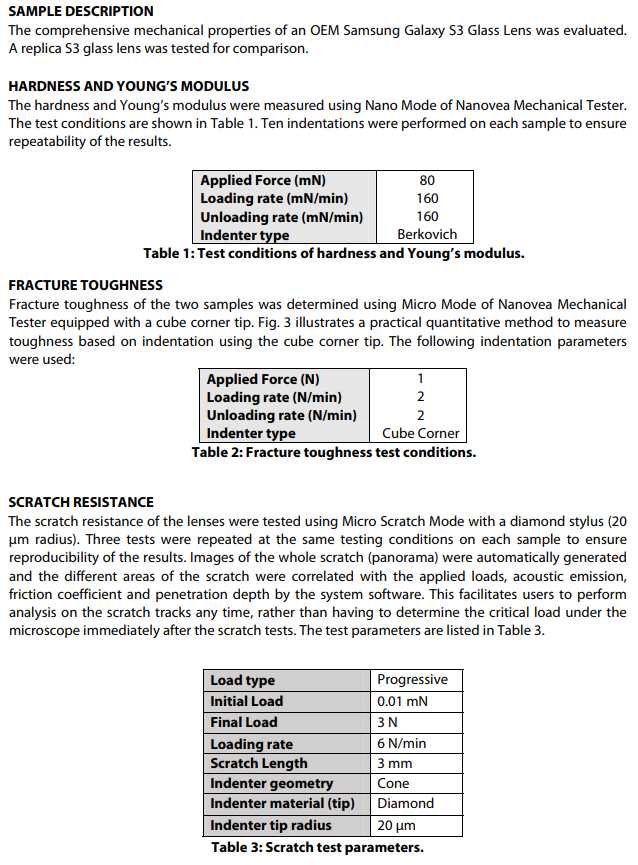

It uses an established method where an indenter tip with a known geometry is driven into a specific site of the material to be tested, by applying an increasing normal load. When reaching a pre-set maximum value, the normal load is reduced until complete relaxation occurs. The load is applied by a piezo actuator and the load is measured in a controlled loop with a high sensitivity load cell. During the experiment the position of the indenter relative to the sample surface is precisely monitored with high precision capacitive sensor.

TEST CONDITIONS & PROCEDURE:

CONCLUSION:

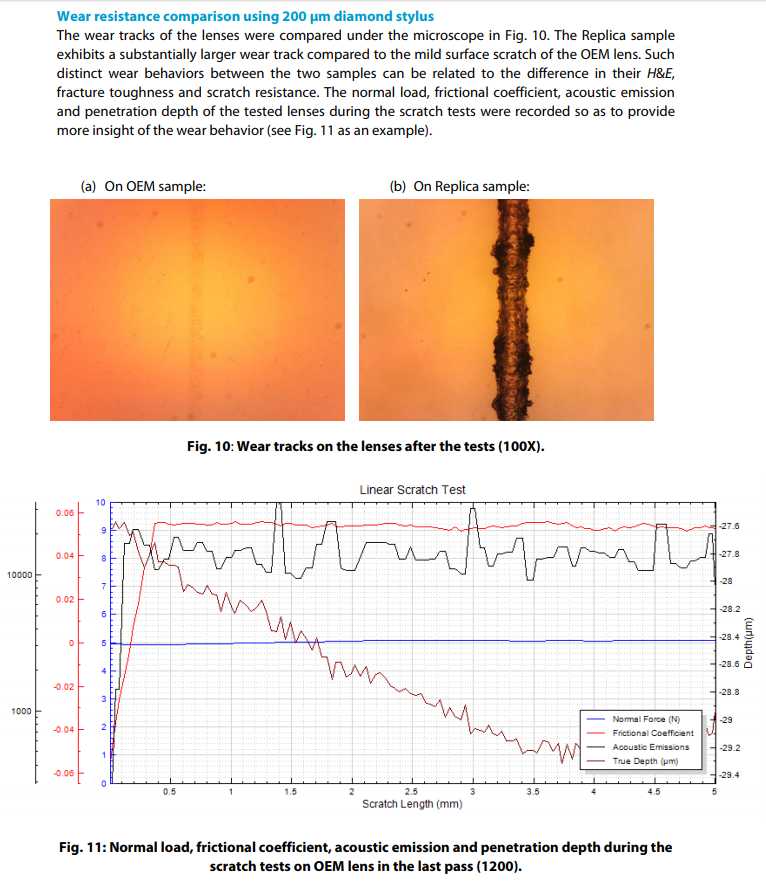

In this study, we show that the Nanovea Mechanical Tester performs accurate and repeatable measurements of complete tribo-mechanical properties of glass samples. The OEM lens possesses higher hardness, Young’s modulus and fracture toughness as well as scratch and wear resistance compared with the Replica one, demonstrating the superior mechanical strength of the OEM lens for phone screen protection.

The Nano, Micro or Macro modules of the Nanovea Mechanical Tester all include ISO and ASTM

compliant indentation, scratch and wear tester modes, providing the widest and most user friendly range of testing available in a single system. Nanovea's unmatched range is an ideal solution for determining the full range of mechanical properties of thin or thick, soft or hard coatings, films and substrates, including hardness, Young’s modulus, fracture toughness, adhesion, wear resistance and many others.

In addition, optional 3D non-contact profiler and AFM Module are available for high resolution 3D imaging of indentation, scratch and wear track in addition to other surface measurements such as roughness.

2019-04-17 16:15