Glow wire Test Procedures

Glow wire testing machine is used for electrical and electronic products, plastic parts of household appliances and non-metallic insulation materials, such as: switch shell, relay socket.It is suitable for electronic products, household appliances and their materials for fire hazard testing. It simulate thermal stress caused by hot components or overload resistance of the heat source or ignition source in a short time.

Test Procedures:

1, The operation before the preparation

2, Be sure to read the using instructions, and follow the instructions step, followed by operation;

3, Do not use non-original accessories, so as to avoid danger;

4, Glow wire test machine should be put in the room that have the oil ventilation equipment (or with a special ventilation hood in a small laboratory), in order to expel the exhaust after the test.

5, The two matching weights with copper wire (connected to the sample rack) by the left side of the two pulleys (through the corresponding hole) hanging under the bracket plate.

6, According to the standard requirements of interest and clamping samples.

7, Close to the adjustment of the switch;

A. The nut that is fixed to the switch is loosened and moved left and right;

B. Press the "left button" car automatically forward, when the sample contact with the hot wire, the hand close the switch, so that the car stopped before the fixed and close the switch;

C. Press the "Heating" button to adjust the current adjustment knob. According to the requirements of the sample, adjust the appropriate current value, while the temperature is required to meet the test requirements of the required temperature;

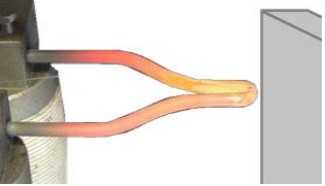

When the test piece touches the glowing wire head, the limit electromagnet is released and the 1N weight can only be moved forward by 7mm;

When the experiment is finished, eject the heating button and then turn the current adjustment knob to the minimum;

2018-05-31 15:01