Test methods to Measure Crocking Colorfastness

Color fastness is a term—used in the dyeing of textile materials—that characterizes a material's color's resistance to fading or running. The term is usually used in the context of clothes. The first known use of the word colorfast was in 1916. In general, clothing should be tested for colorfastness before using bleach or other cleaning products.

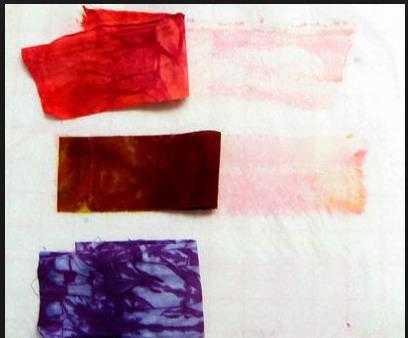

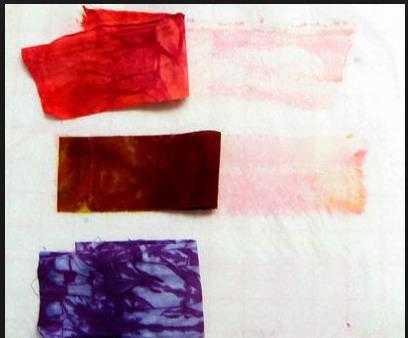

Light fastness, wash fastness, and rub fastness are the main forms of color fastness that are standardized. The light fastness of textile dye is categorized from one to eight and the wash fastness from one to five, with a higher the number indicating better fastness.Colorfastness is a fabric's ability to retain color in various conditions. Tests are performed that involve wet and dry crocking. Crocking refers to the rubbing off of color from a fabric when subjected to abrasion.

One test is the AATCC 8-2001. This "is a test method of the American Association of Textile Chemists and Colorists (AATCC). This method uses a standard white cotton fabric that is rubbed against the surface of the test fabric. To test for wet crocking the standard fabric is wet before rubbing against the test fabric. After rubbing under controlled pressure for a specific number of times the amount of color transferred to the white test squares is compared to an AATCC color chart and a rating is established."

Another test is the AATCC 116-2001. This "is a test method of the American Association of Textile Chemists and Colorists (AATCC). This test is specifically used for printed fabrics that do not lend themselves to the AATCC 8-2001 method. The test fabric is held at the base of a Rotary Vertical Crockmeter and rubbed with a standard cotton white fabric either dry or wet. After rubbing under controlled pressure for a specific number of times the amount of color transferred to the white test squares is compared to an AATCC color chart and a rating is established."

2017-12-29 14:56