Standards and test principles of automotive sealing strip flocking wear tester

The test methods of the automotive seal flocking wear tester include dry grinding and wet grinding tests. The sample is placed in an environment with standard temperature and humidity requirements, and a special grinding head is used to reciprocate the sample at a certain speed under a certain mass load to observe its wear degree. It is developed and produced by our company Shanghai Qianshi Precision Electromechanical Technology Co., Ltd. Welcome to consult.

Compliance with standards:

GB/T 21282-2007 Passenger car rubber and plastic sealing strips

QC/T 642-2000 Vehicle flocking sealing strip wear test method

QC/T 711-2004 Automobile seal flocking wear test method

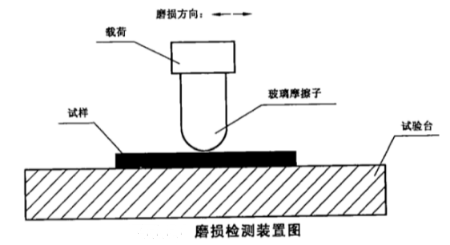

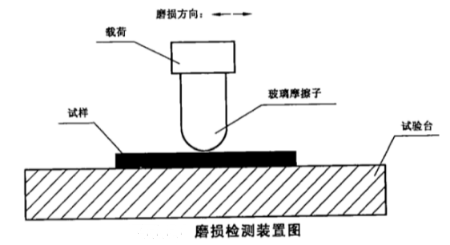

Test principle:

Put the sample (lip or bottom of the sealing strip) flat on the wear tester, and use a special grinding head to reciprocate the sample at a certain speed under a certain mass load to observe its wear degree.

Technical parameters:

Control system: PLC

Operation interface: 7-inch color touch screen, switch between Chinese and English.

Workstation: single or multi-station according to customer requirements

Test piece: 150-220mm

Friction medium: width 20mm, thickness 4mm

Weight of weight: 250, 500, 1000g (optional)

Speed: 0-100r/min adjustable

Counter: touch screen display 0-999999

Friction head size: 20*20mm

Reciprocating stroke: 0-160mm adjustable

2024-11-15 13:09