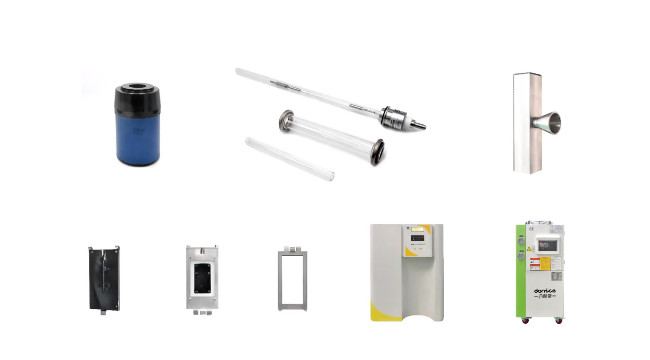

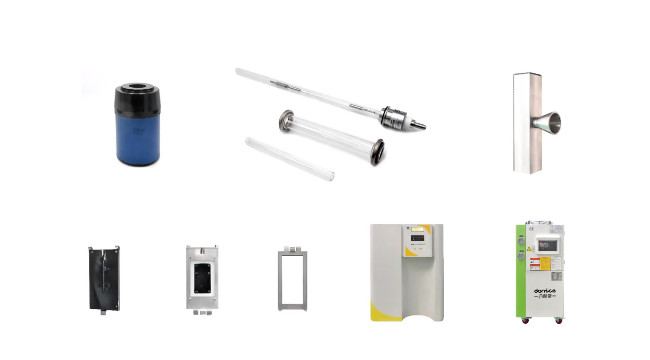

4 major components of UV Accelerated Weathering Tester light source

At present, most of the UV light source products used by UV Accelerated Weathering Tester are mainly composed of UV lamps, capacitors, transformers, and reflectors.

1. UV lamps:

There are currently two types of UV lamps on the market: high-pressure mercury lamps and metal halide lamps. High-pressure mercury lamps are generally used in domestic equipment, and metal halide lamps are used in some imported equipment.

1. Selection of UV lamp power.

The power of the UV lamp is the radiant energy of the UV lamp, also commonly known as the penetrating power. First of all, it must meet the requirements of spectral wavelength and power density absorbed by UV ink (varnish). If the power of the UV lamp is not enough, the product will not be fully cured even if the illumination time is longer and the number of times it passes through the UV fixed phone device. On the contrary, the surface layer of UV ink (varnish) will be aged, closed, brittle, etc. At the same time, the adhesion of the ink (varnish) will not be good, which will make the interlayer bonding force of overprinting poor. Because the low-power UV light cannot penetrate the bottom of the ink layer, the bottom is uncured or insufficiently cured.

2. The power of the UV lamp generally meets the requirements of 80-120W/cm, but the higher the power, the greater the heat. Therefore, the power should be selected according to the different curing materials and curing speeds.

3. The maximum life of the UV lamp is generally 800-1000 hours, and it should be replaced after reaching it, because the intensity of the ultraviolet light emitted by the UV during this period becomes weaker, which will affect the curing effect. At the same time, it is recommended to clean the surface of the lamp tube and the reflector on the surface of the reflector with anhydrous ethanol at an appropriate time according to the production environment (dust content in the air) during the use period, and then turn the UV lamp tube by 90°. In this way, all UV rays can be effectively radiated to the UV ink or varnish to ensure a certain penetrating power.

2. Transformer:

The selection of the transformer must match the power of the UV lamp, that is, the transformer must have enough output voltage to ensure that the UV lamp can work at full power. If the output voltage is too high, the lamp will burn out; if the output voltage is too low, the lamp can not work at full power, so that the ultraviolet output intensity is insufficient.

3. Capacitors:

The selection of capacitors should be matched with lamps and transformers, and the withstand voltage of the capacitors used should be selected according to the output voltage of the transformer. Improper selection will cause the capacitor to break down and affect the normal operation of the UV curing device.

4. Reflector:

The types of reflectors are focused, non-focused and multi-faceted.

QINSUN is a professional UV Accelerated Weathering Tester manufacturer, if you have any customers who want to buy, please contact us!

2022-03-03 10:28