Types and Characteristics of Fabric Manikin for Garment Testing

In many human clothing experiments, Fabric Manikin is often used to replace real people for testing, which can not only avoid the danger of personal safety and negative physiological effects, but also can carry out long and repeated tedious experiments. Conducive to reducing costs and improving accuracy and uniform standards.

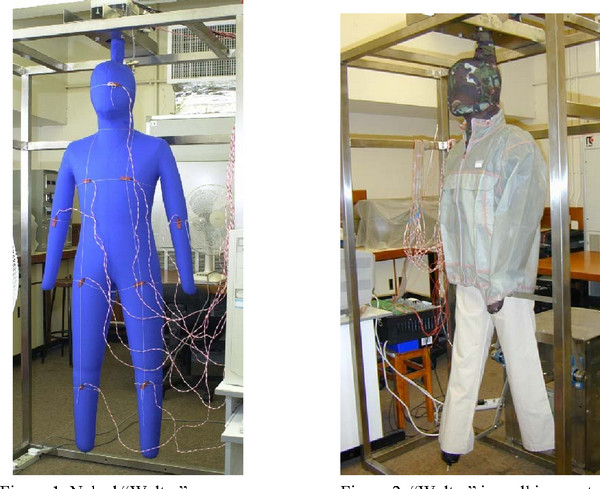

2.1 Warming Fabric Manikin

Warm body Fabric Manikin is a simulation system of human body and clothing. Its basic principle is to use a computer-controlled closed-loop temperature automatic adjustment system to realize the simulation system of human body heat dissipation and perspiration function. By simulating the heat and moisture exchange process between the human body, clothing and the environment , and calculate the heat and humidity evaluation index of clothing according to the state parameters of the three when they are in steady state thermal equilibrium, so as to achieve the purpose of testing [1,2]. The development of the warm body Fabric Manikin began in the 1940s with the first generation of warm body dummies developed by the U.S. Military Climate Research Institute. It can only be used for general testing of thermal resistance of clothing. From the second-generation warm-body Fabric Manikin with different postures to the current third-generation warm-body sweating dummy that can meet various functional requirements, its application range is also wider [3,4]. The warm body Fabric Manikin's simulation of the human body's posture has also changed from the earliest upright static to the present, which can simulate various complex postures of the human body. Many countries will give more consideration to the mobility of Fabric Manikin when developing warm body Fabric Manikin. However, at present, the research and development of the mobility of the Fabric Manikin usually set movable joints in the shoulders, elbows, hips and ankles of the Fabric Manikin. It still needs external force to simulate the action posture of the human body. The range of motion and positioning adopts the bearing friction method [5], which cannot accurately simulate the series of human body dynamics in timing, positioning and constant speed.

2.2 Software Fabric Manikin

Clothing testing software Fabric Manikin is a model developed in recent years for testing the pressure comfort of clothing. Due to the requirement of a high degree of simulation of the body structure and skin of the human body, the requirements for the production materials are relatively high, and the soft and elastic texture of human skin must be well simulated in order to meet the requirements of clothing comfort and clothing pressure testing. Research. In 2005, Yu Yongwen from the Department of Textiles and Clothing, Hong Kong Polytechnic University, et al. [6] developed the world's first software Fabric Manikin, which is mainly used for static clothing display, comfort and pressure testing research.

In order to make the soft Fabric Manikin meet the needs of dynamic body shape experiments, in 2008, Donghua University [7] developed a soft lower body movable soft body for adult women, Fabric Manikin. The inner layer of the soft Fabric Manikin uses a standard bone model as the basic component, and the outer layer is made of materials similar to human skin texture. By setting artificial joints and airbag devices at the hip and knee joints, it can simulate human standing and bending. , squat and other postures. Among them, the hip joint of the Fabric Manikin is driven by spherical bearing friction, and the knee joint is driven by a manual adjustment of the turbine worm drive. It is not yet possible to control its mobility at a fixed speed from within the Fabric Manikin.

2.3 Burning Fabric Manikin

Burning Fabric Manikin is to simulate the human body in a combustion environment with controllable heat flow, flame distribution and duration under laboratory conditions. Through the information detection of clothing and Fabric Manikin skin surface, the corresponding skin burn index is used to objectively Quantitatively evaluate the burn degree of the human body and the overall thermal protection performance of protective clothing [8]. Burning Fabric Manikin first originated from the male Fabric Manikin used by the U.S. Navy in 1962 to test the thermal protection performance of Air Force clothing. In the 1980s, the University of Minnesota also built an adult female Burning Fabric Manikin with 44 thermocouple sensors on the body. By the end of the 1980s, the University of Alberta in Canada also developed a Fabric Manikin similar to the Naval Institute. The Fabric Manikin has 110 heat flow sensors installed on the surface. In recent years, it is more representative of the combustion Fabric Manikin system developed by North Carolina State University in the United States and the Protective Equipment Center of the Department of Human Ecology at the University of Alberta in Canada.

To learn more about the Walter Sweating Fabric Manikin, drop us a note!

2022-02-11 11:40