Site: Home > News and events

The hydrostatic pressure test of the fabric and its influencing factors

Hydrostatic pressure tester is one of the important indexes of waterproof and moisture-permeable fabrics. Hydrostatic pressure refers to the resistance encountered when water passes through the fabric. Under standard atmospheric pressure conditions, the fabric is subjected to continuously rising water pressure until water drops leak out from the back of the fabric. At this time, the measured water pressure is the hydrostatic pressure. The greater the hydrostatic pressure that the fabric can withstand, the better the water resistance or leakage resistance.

Influencing factors of fabric resistance to hydrostatic pressure:

The level of the waterproof index of the waterproof and moisture-permeable fabric depends on the following factors:

(1) The tightness of the fabric. The increase in the distance between the yarns will directly affect the water pressure resistance. Generally, the tighter the fabric structure, the better its water permeability.

(2) The size of the pore size of the coating membrane. The larger the pore diameter of the membrane, the worse the hydrostatic pressure resistance of the coated fabric.

(3) The size of the contact angle 0. When 0>90. At this time, the fabric has water-repellent properties. At this time, with the increase of 0, the water pressure resistance value of the fabric also increases accordingly.

(4) Coating thickness. If the coating is too thin, the coating agent will not easily form a continuous film on the surface, and the water pressure resistance of the coated fabric will decrease; if the coating is thick, the water pressure resistance of the fabric will increase.

(5) The thickness of the fabric. The thicker the fabric, the greater the moisture resistance and the greater the water pressure resistance value.

(6) The thickness of the yarn. For compact fabrics woven from fibers with good moisture absorption, due to the capillary effect, reducing the yarn radius can improve the fabric's water permeability.

(7) The performance of warp and weft yarns is good or bad. Under the action of water pressure, the warp and weft yarns with good elasticity are easy to stretch, which leads to the formation of gaps between adjacent warp and weft yarns.

(8) Coating quality. The entire cloth surface is required to be uniform and have a certain fastness. The better the coating quality, the better the water seepage resistance.

Fabric resistance to hydrostatic pressure test method:

Classified by test method:

(1) Field test. Field tests are expensive and time-consuming, usually about half a year. During the experiment, regularly test the waterproofness of the fabric after the waterproof and moisture-permeable finishing, so as to know its durability. Although this method has a long cycle and a lot of cost, the data obtained by the test is accurate.

(2) Simulation test. The simulation test must have an environmental control room. The chamber is equipped with an artificial rain tower, which can discharge water from a height of 10m at a flow rate of 450L/m·h to the mannequin like a torrential rain. Water droplets with a diameter of about 5inln are sprayed from the top 2000 holes at a speed of about 40km. /H, reaching 90% of the maximum raindrop speed in the air. Through adjustment, showers of different degrees can be imitated on an area of about 2m. The surface of the human body model is filled with sensors, the purpose of which is to determine the time and location of the final water penetration and other indicators. This method of testing is much shorter than the time required for field testing, and can be completed within a few days, but the cost is relatively high.

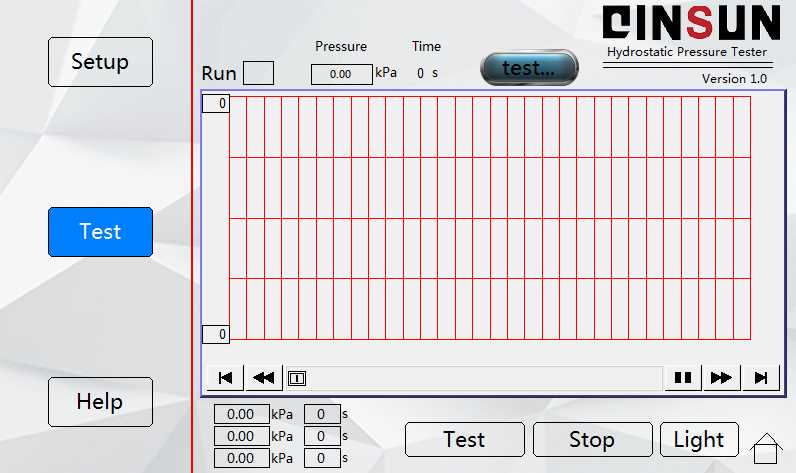

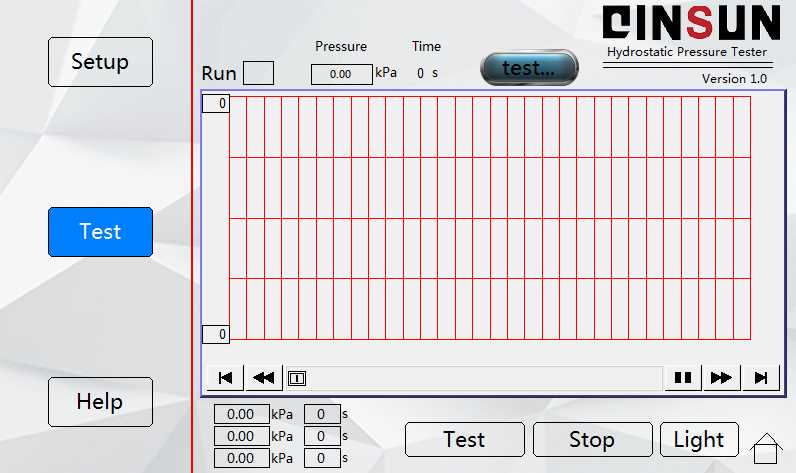

(3) Laboratory test. Compared with field test and simulation test, laboratory test is less expensive, shorter time, can get relative results, and is more practical. The test of the waterproofness of the fabric after the waterproof and moisture-permeable finishing can be divided into three categories. The first category is hydrostatic pressure test, such as domestic fabric hydrostatic pressure tester, American Standard Test Method ASTM D-751 and American Federal Standard Test Method FED-STD-191A5512 Mullen Hydrostatic Tester. The second type is the spray test, which means that water is continuously dripped or sprayed on the fabric to be tested from a certain height and angle. It can measure the time required for water to penetrate from the side of the fabric to the other side, and it can also measure the elapsed time. Then, the amount of water absorbed by the sample or observe the water stain state of the sample. The domestic ISO4920 rainproof performance test adopts this principle.

Classified according to the form of pressure:

(1) Dynamic method. Continuously increase the water pressure on one side of the fabric, and measure the hydrostatic pressure that the fabric can withstand until a specified number of water drops appear on the other side of the fabric.

(2) Static method. Maintain a certain water pressure on one side of the fabric and measure the time it takes for water to penetrate from one side to the other.

is classified according to the size that can withstand the hydrostatic pressure:

(1) Low voltage test method. Standard test methods include the low-pressure method in the Chinese national standard GB/74744-1997 "Determination of Water Resistance of Textile Fabrics by Hydrostatic Pressure Test"; Chinese industry standard FZ/T01004-1991 "Determination of Water Resistance of Coated Fabrics by Hydrostatic Pressure Test" ; Canadian Standard (CGSB)_-4. 2No. 26.3-1995 "Textile fabric impermeability determination hydrostatic pressure test"; International standard ISO1420-1987 "Rubber and plastic coated fabric impermeability determination hydrostatic pressure test"; Japanese Industrial Standard JISL-1092 ((textile resistance Hydrostatic Hydrostatic Test A"; American Textile Chemists and Dyeers Association Standard AATCC127 (Textile Water Resistance Hydrostatic Test"; American Standard Testing Method (or American Society for Testing and Materials Standard) ASTM D751-1995 (Water resistance of coated fabrics) Determination of B" and other methods.

(2) High voltage test method. Standard test methods include the high-pressure method in FZ/T01004-1991 "Determination of Water Resistance of Coated Fabrics by Hydrostatic Pressure Test"; ISO1420-1987~Determination of Water Resistance of Rubber and Plastic Coated Fabrics by Hydrostatic Pressure; JISL-1092 (Textile Water Resistance Hydrostatic Pressure Test B"; ASTM D751-95 "Test Procedure A for Water Resistance of Coated Fabrics"; US Federal Standard Testing Method FED-STD-191A 5512 and ASTM D3393 ((Description of Waterproof Standard for Coated Fabrics" And other methods.

https://www.youtube.com/watch?v=bCAU81MlVjk&t=18s

https://www.youtube.com/watch?v=bCAU81MlVjk&t=18s

2021-03-22 23:09