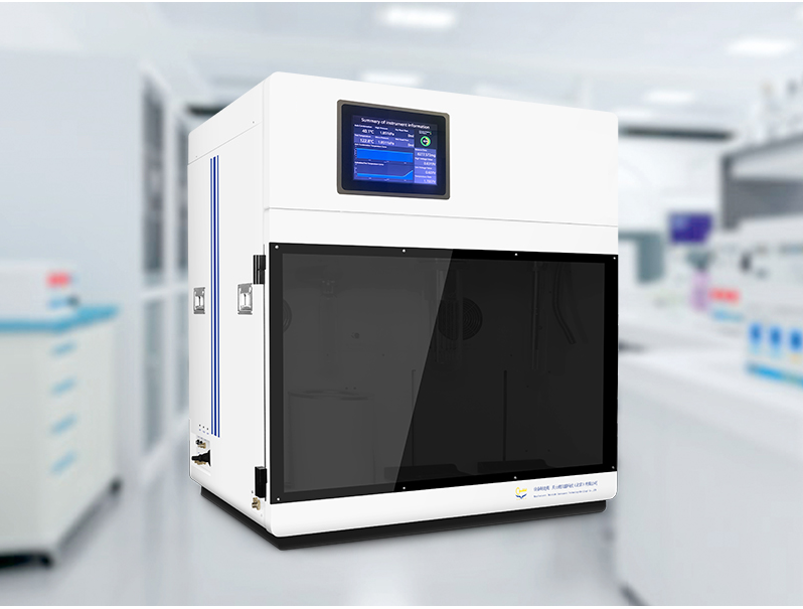

Single Burning Item (SBI) Tester

Introduction

Single Burning Item (SBI) tester is planned to classify the building materials (except floorings) complaints to the thermal attack of a single burner according to EN 13823. The sample is mounted on a suitable trolley under an aspiration hood. The reaction of sample comes monitored both in a visual and instrumental way.

Fire hazard test method is used to evaluate the material or components performance in the fire. It is the best grading evaluation way for the material combustion and flame retardant performance by a unified and accurate test method, which can be effectively early warned and prevented in the source of the fire. Through the monomer combustion test, the material performance can be effectively assessed to provide reliable data on the new and modified product. And provide test service for the existing product quality and the market product sampling and control, Third-party test performance.

Unlike the previous test method, the SBI monomer combustion test method developed by the European Technical Commission in 1999 aims to provide a more comprehensive, more authoritative, more extensive test standard for the evaluation of building materials’ combustion performance, and to harmonize the building materials performance evaluation criteria, eliminate the existence of their own political and regulatory barriers to the establishment of a unified building materials market. EN 13823 has been the national standard for countries such as Britain, France, Germany, Switzerland, Sweden, Australia, Italy, Belgium, Czech Republic, Denmark, Finland, Greece, Iceland, Ireland, the Netherlands, Norway, Spain, Portugal, et al. More and more national standards move closer to the international standards.

Standards

EN 13823 Reaction to fire tests for building products ― Building products excluding floorings exposed to the thermal attack by a single burning item

Principle

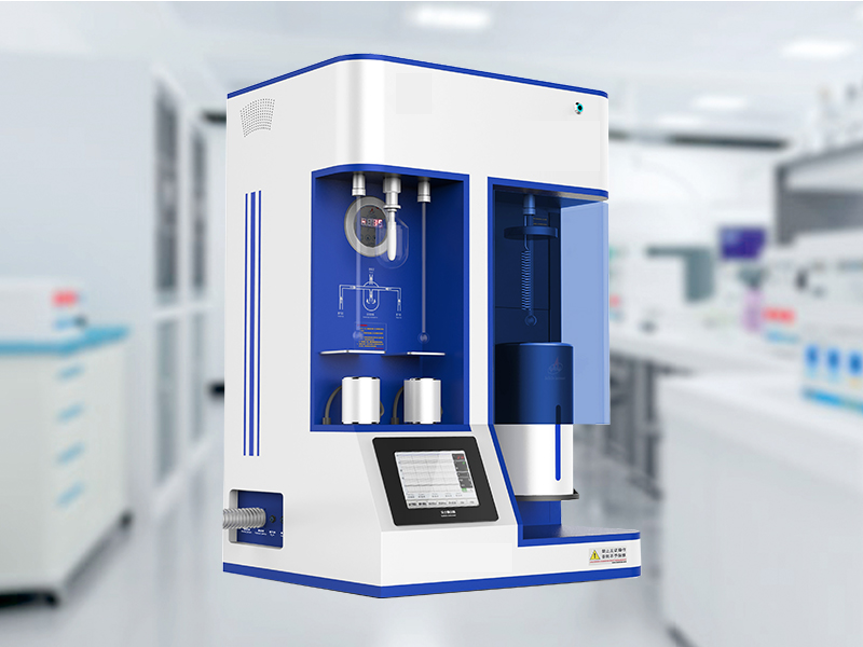

Single Burning Item (SBI) test method and the heat release rate test method and the corner flame test method, are using the principle of oxygen consumption test material on the fire reaction characteristics, mainly simulated fire behavior of product near the corner to assess the potential contribution of fire spread and the smoke generation.

1. Record the storage parameters of the test process data acquisition system (3s-1)

Time (s).

2. Triangular sandbox burner propane gas mass flow (mg/s).

3. Comprehensive test end differential pressure (Pa).

4. Relative light intensity

5. O2 concentration (VO2/Vair)%.

6. CO2 concentration (VCO2/Vair)%.

7. The environment temperature of the air inlet at the bottom of the test bed (K).

8. The temperature of three thermocouples on Comprehensive test period (K).

Main test parameters:

1. FIGRA flame growth rate (W/s).

2. THR600s, Total heat release of sample exposed to the burner flame in the first 600s (MJ).

3. SMOGRA smoke growth rate (W/s).

4. TSP600s, Total amount of smoke production of sample exposed to the burner flame in the first 600s (m2).

5. Spread the flame from the long wing of LFS sample to the side of the sample (m).

Single Burning Item (SBI) tester is planned to classify the building materials (except floorings) complaints to the thermal attack of a single burner according to EN 13823. The sample is mounted on a suitable trolley under an aspiration hood. The reaction of sample comes monitored both in a visual and instrumental way.

Fire hazard test method is used to evaluate the material or components performance in the fire. It is the best grading evaluation way for the material combustion and flame retardant performance by a unified and accurate test method, which can be effectively early warned and prevented in the source of the fire. Through the monomer combustion test, the material performance can be effectively assessed to provide reliable data on the new and modified product. And provide test service for the existing product quality and the market product sampling and control, Third-party test performance.

Unlike the previous test method, the SBI monomer combustion test method developed by the European Technical Commission in 1999 aims to provide a more comprehensive, more authoritative, more extensive test standard for the evaluation of building materials’ combustion performance, and to harmonize the building materials performance evaluation criteria, eliminate the existence of their own political and regulatory barriers to the establishment of a unified building materials market. EN 13823 has been the national standard for countries such as Britain, France, Germany, Switzerland, Sweden, Australia, Italy, Belgium, Czech Republic, Denmark, Finland, Greece, Iceland, Ireland, the Netherlands, Norway, Spain, Portugal, et al. More and more national standards move closer to the international standards.

Standards

EN 13823 Reaction to fire tests for building products ― Building products excluding floorings exposed to the thermal attack by a single burning item

Principle

Single Burning Item (SBI) test method and the heat release rate test method and the corner flame test method, are using the principle of oxygen consumption test material on the fire reaction characteristics, mainly simulated fire behavior of product near the corner to assess the potential contribution of fire spread and the smoke generation.

1. Record the storage parameters of the test process data acquisition system (3s-1)

Time (s).

2. Triangular sandbox burner propane gas mass flow (mg/s).

3. Comprehensive test end differential pressure (Pa).

4. Relative light intensity

5. O2 concentration (VO2/Vair)%.

6. CO2 concentration (VCO2/Vair)%.

7. The environment temperature of the air inlet at the bottom of the test bed (K).

8. The temperature of three thermocouples on Comprehensive test period (K).

Main test parameters:

1. FIGRA flame growth rate (W/s).

2. THR600s, Total heat release of sample exposed to the burner flame in the first 600s (MJ).

3. SMOGRA smoke growth rate (W/s).

4. TSP600s, Total amount of smoke production of sample exposed to the burner flame in the first 600s (m2).

5. Spread the flame from the long wing of LFS sample to the side of the sample (m).

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price