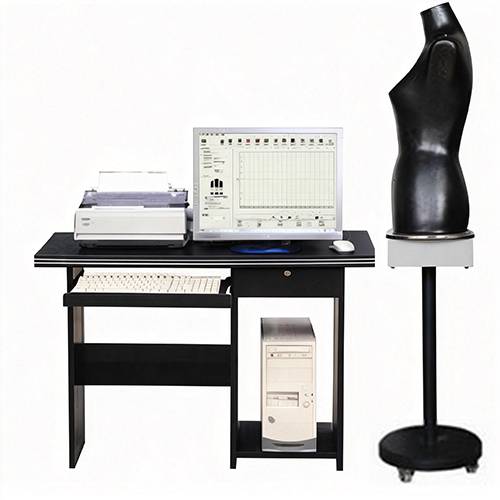

Airbag-Type Contact Pressure Tester

The Airbag-Type Contact Pressure Tester is designed to evaluate contact pressure between garments, hosiery, wearable devices, and the human body. It allows you to accurately assess wearing comfort, garment functionality, and user experience for clothing design, textile research, sock development, and ergonomic studies.

Application

You use this tester to measure contact pressure in:

Functional garments such as compression wear and sportswear

Medical and therapeutic hosiery (e.g., pressure socks and sleeves)

Wearable devices that interact with the human body

Ergonomic studies of clothing fit and comfort

Textile material R&D for clothing and accessories

Standards

The Airbag-Type Contact Pressure Tester complies with the following standards:

(1) FZ/T 73031-2009 Pressure socks

(2) DD ENV 12718-2001 Medical compression knitted fabrics

(3) CEN/TR 15831 Test methods for medical sock compression performance

(4) RAL-GZ 387/1 Pressure testing for compression hosiery products

(5) RAL-GZ 387/2 Pressure performance testing of medical pressure textiles (e.g., socks, sleeves)

Parameters

| Item | Specification |

|---|---|

| Measurement Points | 1 |

| Force Sensor | Ultra-soft, non-stretch airbag, thickness <1 mm; fully contacts the human body and flexible fabrics to detect micro pressure changes accurately |

| Measurement Range | 0–38.00 kPa ±0.1 kPa |

| Measurement Accuracy (23℃) | ±0.1 kPa |

| Measurement Interval | Minimum 100 ms, high repeatability, minimally affected by temperature |

| Display & Control | Large color touchscreen, Chinese/English interface |

| Maximum Airbag Pressure | ≤100 kPa |

| Operating Environment | 0–45℃, relative humidity 25–85% |

| Power Supply | AC 220V, 50Hz, 1000W |

| Instrument Dimensions (W×D×H) | 400×450×1500 mm |

| Instrument Weight | 150 kg |

Features

You can perform dynamic, continuous measurement of contact pressure on the human body in different motion states.

The instrument includes a dedicated calibration device for accurate testing.

A full-color touchscreen with dual-language interface simplifies operation.

The floor-standing design with metal finish and adjustable caster wheels ensures stability and mobility in the lab environment.

Leg forms are 3D-printed, compliant with national and international standards for pressure measurement.

The ultra-thin airbag sensor provides real-time, highly accurate reflection of garment pressure on the body.

Accessories

(1) Main testing unit

(2) Airbag force sensors

(3) 3D-printed mannequin/leg forms

(4) Calibration device

(5) Power cable

(6) User manual

(7) Certificate of conformity

Test Procedures

You place the airbag sensors on the mannequin or leg forms.

Dress the garment or hosiery to be tested.

Set measurement parameters and start the test via the touchscreen.

The system records dynamic pressure data as the mannequin simulates different postures or movements.

After the test, you can analyze pressure distribution and variations through the software interface.

Maintenance Information

You should regularly check and calibrate airbag sensors to maintain measurement accuracy.

Clean the sensor surfaces and mannequin forms to prevent contamination.

Inspect mechanical components and caster wheels for smooth operation.

Ensure the touchscreen interface and software are updated and functioning properly for consistent results.

FAQ

1.What is this product?

This product is a tester that measures contact pressure between garments or hosiery and the human body using airbag-type sensors.

2.What is this product used for?

You use it to evaluate wearing comfort, garment functionality, and user experience in textiles and wearable devices.

3.What is the working principle of this product?

It uses ultra-thin airbag sensors to detect micro pressure changes on the body while the mannequin simulates motion.

4.Why is this product important?

It provides objective data on garment pressure distribution, helping optimize comfort, performance, and ergonomic design.

5.What industries is this product suitable for?

It is suitable for textile R&D, garment manufacturing, medical compression product development, wearable devices, and ergonomic research.

Leave Message Get Price