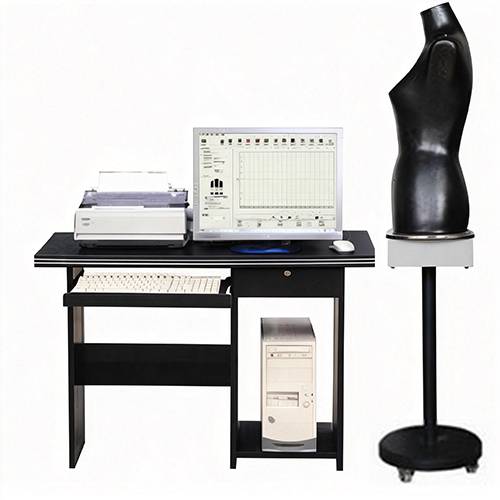

Cable Fire Resistance and Circuit Integrity Test Machine

The Cable Fire Resistance and Circuit Integrity Test Machine is designed to evaluate the ability of mineral insulated cables and fire-resistant electric wires and cables to maintain circuit integrity under direct flame exposure.

You can use this system to perform controlled fire tests where individual cable specimens are exposed to a gas flame under specified temperature, duration, and electrical load conditions. During the test, the system continuously monitors short-circuit or open-circuit conditions to determine fire resistance performance.

The equipment is suitable for type testing, factory acceptance testing, and research verification of fire-resistant cables.

Application

You can apply this test machine to the following products and test scenarios:

Mineral insulated cables (MI cables)

Power cables with fire-resistant layer structures

Fire-resistant building wires

Low-voltage control cables and signal cables

Fire-resistant optical cables and composite cables

Fire-resistant cables with rated voltage up to 450/750 V

Verification of combined properties such as fire resistance, flame retardancy, and water–fire resistance

Typical users include cable manufacturers, building electrical testing institutions, fire protection product testing centers, research institutes, and third-party laboratories.

Standards

The system is designed to comply with or support the following standards:

(1) GB/T 19216-2008 Circuit integrity test of cables or optical cables under fire conditions

(2) GB/T 19666-2019 General requirements for flame-retardant and fire-resistant electric wires and cables

(3) IEC 60331-2009 Tests for electric cables under fire conditions – Circuit integrity

(4) BS 6387 Performance requirements for cables required to maintain circuit integrity under fire conditions

(5) BS 8491 Method for assessment of cable fire resistance and circuit integrity

Parameters

| Item | Specification |

|---|---|

| Test stations | 1 station (single specimen testing) |

| Specimen length | ≥ 1200 mm |

| Burner type | Propane strip burner with Venturi mixer |

| Burner nominal length | 500 mm |

| Gas flow range | 0–50 L/min, adjustable |

| Gas flow accuracy | 0.1 L/min |

| Air flow range | 0–200 L/min, adjustable |

| Air flow accuracy | 5 L/min |

| Flame temperature range | 450 °C to 950 °C, adjustable |

| Temperature sensors | K-type stainless steel thermocouples ×2 |

| Thermocouple temperature limit | ≤ 1100 °C |

| Control system | PLC control with touch screen operation |

| Operating power | 3 kW |

| Power supply | AC 380 V ±10 %, 50 Hz, three-phase five-wire |

| Gas supply | Propane or LPG with compressed air |

Features

Mass flow controllers provide high-precision closed-loop control of gas and air flow

Wide flame temperature adjustment range to meet different fire resistance grades

Circuit breaker-based short-circuit detection improves reliability and maintenance efficiency

Continuous electrical monitoring allows real-time detection of open or short circuits

Side-mounted exhaust system ensures stable oxygen concentration during combustion

PLC and touch screen control enable intuitive parameter setting and high repeatability

Compatible with combined fire resistance tests, including water spray and mechanical impact conditions

Accessories

(1) Strip propane burner assembly

(2) Gas and air mass flow control units

(3) K-type thermocouples

(4) Electrical continuity monitoring module

(5) Exhaust and ventilation components

Test Procedures

Install the cable specimen on the test frame according to the selected standard.

Connect the electrical circuit and continuity monitoring system.

Set flame temperature, gas flow, air flow, and test duration via the touch screen.

Ignite the burner and expose the specimen to the controlled flame.

Monitor circuit integrity continuously during the test.

Record short-circuit or open-circuit events and determine test results after completion.

Maintenance Information

Regularly inspect burners, gas pipelines, and flow controllers for leakage or blockage.

Calibrate thermocouples and flow control devices periodically.

Clean combustion residues from the test chamber after each test.

Verify electrical monitoring circuits before each test cycle.

Maintain proper ventilation and exhaust performance to ensure stable combustion.

FAQ

What is this product?

It is a fire resistance and circuit integrity test machine for electric wires and cables under flame exposure.

What is this product used for?

You use it to evaluate whether cables can maintain electrical continuity during a fire.

How does this product work?

It exposes a cable specimen to a controlled gas flame while continuously monitoring electrical continuity.

Why is this product important?

It ensures that fire-resistant cables can continue supplying power or signals during fire emergencies.

Which industries is this product suitable for?

Cable manufacturing, building electrical testing, fire protection testing, research institutes, and third-party laboratories.

Leave Message Get Price