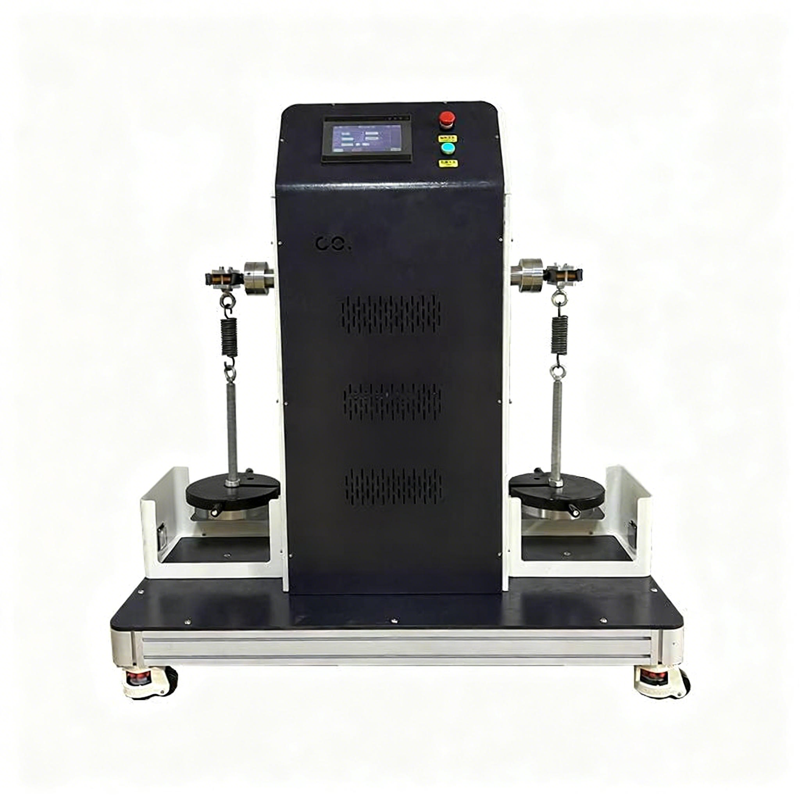

Bicycle Bottom Bracket Abrasion Tester

The Bicycle Bottom Bracket Abrasion Tester is designed to evaluate the rotational durability of bicycle bottom brackets. The tester precisely controls load, rotational speed, and cycle count to simulate long-term usage conditions, assessing wear resistance and structural reliability. The system supports automatic stop functionality, halting the test when the preset cycle count is reached or the specimen fails, ensuring both safety and test reliability.

Application

This tester is suitable for:

(1) Rotational durability testing of all types of bicycle bottom brackets

(2) Bottom bracket structure optimization and new material validation

(3) Quality control and random inspection in bicycle manufacturing

(4) Use by third-party testing agencies and research laboratories

(5) Performance verification for mountain bikes, road bikes, and city bikes

Compliance Standards

(1) QB/T 1884-2018 — Test Method for Bicycle Bottom Bracket Abrasion

Technical Parameters

| Item | Technical Specification |

|---|---|

| Load Weight | 100 kg (10 kg per weight, two sets configurable) |

| Test Speed | 100 ± 2.5 r/min |

| Test Cycles | 0 – 999,999 (adjustable) |

| Loading Method | Motor-driven rotation |

| Control Method | PLC + touchscreen control |

| Power Supply | AC 220 V |

| Frame Structure | Sheet metal with baked paint finish |

| Automatic Stop Function | Stops when preset cycles reached or specimen failure occurs |

Features

(1) Precise control of load, rotational speed, and cycle count

(2) Automatic stop function ensures safety of device and specimen

(3) Customizable test cycles for long-term durability evaluation

(4) PLC touchscreen control for intuitive operation

(5) Robust structure with sheet metal and baked paint finish

Accessories

| Accessory / Consumable | Description |

|---|---|

| Weights | 10 kg per piece, configurable as two sets |

| PLC Control System | Touchscreen interface, user-friendly operation |

| Motor Drive | Provides constant rotational speed |

| Test Fixtures | Suitable for various bottom bracket specifications |

| Machine Base | Provides stable support and vibration reduction |

| Lubricants / Maintenance Consumables | For periodic maintenance |

Test Principle

The device rotates the bicycle bottom bracket via a motor while applying a constant load using weights or a force application system. The PLC controls rotational speed and cycle count in closed-loop, automatically stopping when the preset number of cycles is reached or when the bottom bracket fails. This setup ensures repeatable, safe, and accurate abrasion testing.

Operation Instructions

(1) Mount the bottom bracket securely in the test fixture.

(2) Connect the main power and start the PLC touchscreen interface.

(3) Set test parameters: load, rotational speed, and number of cycles.

(4) Start the test; the device rotates the bottom bracket and applies load automatically.

(5) Monitor rotational speed and cycle count in real time.

(6) The system automatically stops when the preset cycles are reached or the specimen fails.

(7) Periodically check the machine, fixtures, and motor; maintain lubrication and cleanliness.

Test Procedures

(1) Install the bottom bracket in the fixture and secure it.

(2) Set test parameters: load weight, rotational speed, and number of cycles.

(3) Start the rotational abrasion test; the system automatically tracks cycle count.

(4) The machine automatically stops when the set cycles are reached or specimen failure occurs.

(5) Inspect the bottom bracket for wear, deformation, or damage.

(6) Record the test data and compile the test report.

Maintenance Information

(1) Regularly inspect fixtures, weights, and motor for wear or damage.

(2) Keep all moving parts lubricated and free of debris.

(3) Verify calibration of rotational speed and load sensors periodically.

(4) Ensure the PLC control system is updated and functioning properly.

FAQ

1. What is this tester?

It is a bicycle bottom bracket abrasion tester designed to simulate long-term rotational use and evaluate wear resistance.

2. What is this tester used for?

It assesses the durability and structural integrity of bottom brackets under controlled load and rotational conditions.

3. How does it work?

The motor rotates the bottom bracket under a constant load, with PLC closed-loop control monitoring cycles and speed. Automatic stop occurs when cycles are reached or the specimen fails.

4. Why is this tester important?

It ensures the reliability and longevity of bicycle bottom brackets, providing data for quality control, material selection, and product development.

5. What industries is it suitable for?

Bicycle manufacturers, quality control labs, R&D centers, and third-party testing agencies.

Leave Message Get Price