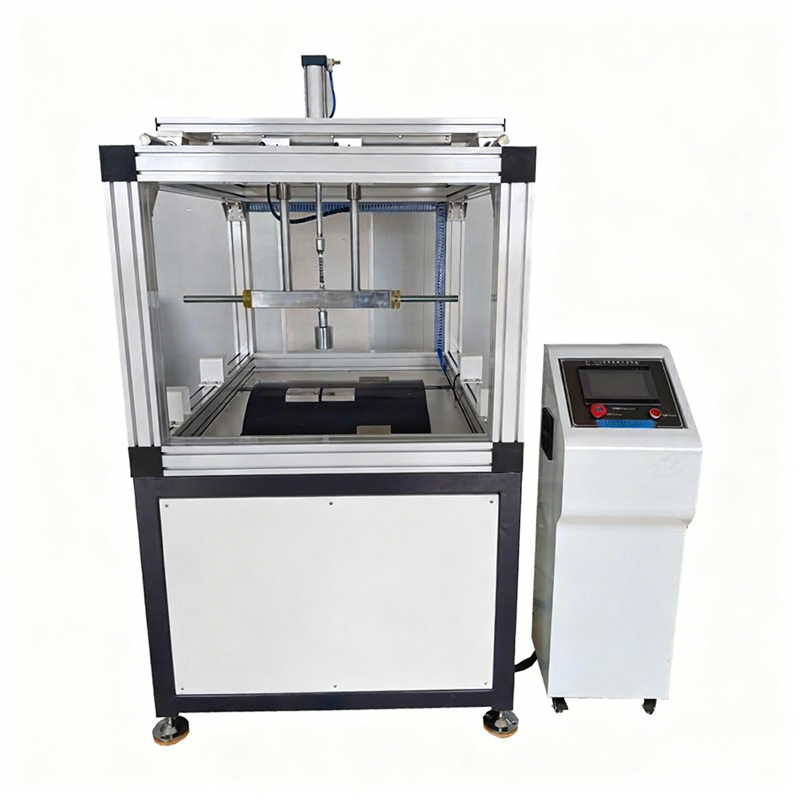

Roller Skate Dynamic Durability Testing Machine

The Roller Skate Dynamic Durability Tester is designed to help you simulate real-world rolling, walking, and impact conditions experienced by inline skates, scooters, and kick scooters during actual use.

By combining a large-diameter roller system with a controllable loading mechanism, the tester allows you to perform long-distance dynamic rolling, fatigue endurance, and wheel wear tests.

This equipment is suitable for product development validation, type testing, and quality control, enabling you to accurately evaluate the dynamic durability of complete products and critical components.

Application

Based on real usage conditions of inline skates and small wheeled mobility products, and referencing common industry testing practices, you can use this tester for the following applications and products:

(1) Dynamic durability testing of inline skates, including recreational, freestyle, and speed skates

(2) Wheel wear resistance and rolling life evaluation of inline skate wheels

(3) Full-vehicle dynamic endurance testing of children’s and adult scooters

(4) Fatigue performance testing of wheel systems and structures for kick scooters

(5) Continuous rolling reliability and wheel run-out testing of scooters

(6) Long-distance rolling durability validation for small wheeled personal mobility products

Standards

The Inline Skate Dynamic Durability Tester is designed to comply with, and support testing according to, the following international and national standards:

(1) GB 20096-2006 — Inline Skates: Safety Requirements and Test Methods

(2) ASTM F2264-14 — Standard Test Methods for Inline Skating Systems

(3) EN 13843:2003 — Roller Sports Equipment – Inline Skates – Safety Requirements and Test Methods

(4) EN 13613:2001 — Roller Sports Equipment – Skateboards – Safety Requirements and Test Methods

(5) EN 14619:2004 — Roller Sports Equipment – Kick Scooters – Safety Requirements and Test Methods

Parameters

| Item | Technical Specification |

|---|---|

| Roller size | 700 mm × 1000 mm |

| Speed range | 0–18 km/h (variable frequency, stepless control) |

| Maximum test load | 140 kg |

| Weight configuration | 20 kg × 4 + 10 kg × 4 + 5 kg × 4 |

| Control system | PLC with touchscreen interface |

| Test mounting space | 1000 × 300 × 1200 mm |

| Frame material | Aluminum alloy + painted sheet metal |

| Drive system | Motor-driven roller system |

| Program functions | Distance setting, speed setting, time setting, power-off memory |

| Overall dimensions | 2000 × 1000 × 2130 mm |

| Equipment weight | Approx. 600 kg |

Features

(1) Large-diameter roller design realistically simulates actual rolling and road contact conditions

(2) Supports dynamic endurance, long-distance rolling, and static load test modes

(3) Variable frequency speed control provides smooth operation and stable performance

(4) PLC touchscreen control allows intuitive parameter setting and high test repeatability

(5) Automatic operation based on total distance or test time to meet multiple standard requirements

(6) High-capacity loading system accommodates different product weights and test conditions

(7) Rigid mechanical structure ensures reliable operation during long-duration endurance tests

Accessories

(1) Standard loading weight set

(2) Adjustable product mounting fixtures

(3) PLC touchscreen control panel

(4) Safety protection and limit devices

(5) Operation and maintenance manual

Test Procedures

(1) Securely mount the inline skates, scooter, or test sample onto the fixture

(2) Select the required test speed, load, and total distance or test duration

(3) Set the roller rotation direction and confirm all safety protections are active

(4) Start the test and allow the equipment to run continuously under the defined conditions

(5) Monitor test operation and record any abnormal behavior during the test

(6) Stop the test automatically upon reaching the preset distance or time

(7) Inspect the test sample for wear, fatigue, structural damage, or functional failure

Maintenance Information

(1) Regularly inspect the roller surface and clean debris to maintain consistent friction conditions

(2) Check loading weights and fixtures to ensure secure installation before each test

(3) Periodically inspect the drive system and lubrication points

(4) Verify PLC control functions and safety interlocks on a routine basis

(5) Keep the equipment clean and operate it in a dry, well-ventilated laboratory environment

FAQ

1. What is this product?

It is a dynamic durability testing machine designed to evaluate the rolling endurance, fatigue performance, and wheel wear of inline skates and small wheeled mobility products.

2. What is this product used for?

You use it to simulate long-distance rolling and real-world usage conditions for inline skates, scooters, and kick scooters during product development, certification testing, and quality control.

3. What is the working principle of this product?

The tester drives a large roller using a motor system. Test samples roll continuously under controlled speed and load, creating repeated friction and impact to simulate actual use conditions.

4. Why is this product important?

It allows you to objectively evaluate product durability, identify potential design weaknesses, and ensure compliance with relevant safety and performance standards.

5. What industries is this product suitable for?

It is suitable for manufacturers, testing laboratories, certification bodies, and R&D centers in the sports equipment, personal mobility, and consumer product industries.

6. What types of this product are available?

The tester can be configured for different load capacities, roller sizes, and control options to meet various inline skate and scooter testing requirements.

Leave Message Get Price