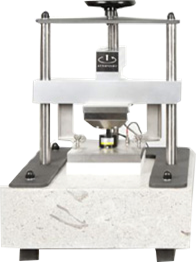

Smoke Optical Density Tester (ISO 5659-2 / EN 45545-2)

The Smoke Optical Density Tester is designed to determine the specific optical density of smoke generated by solid materials mounted in a vertical position. The test chamber is fully sealed and equipped with a truncated conical radiant furnace, providing a variable radiant heat flux range from 10 to 50 kW/m².

The integrated photometric system measures changes in light transmittance caused by smoke generation. All test data and calculated specific optical density values are displayed, processed, and stored via a personal computer. The instrument is suitable for fire safety evaluation of materials where smoke generation and visibility reduction are critical performance indicators.

Applications

The Smoke Optical Density Tester is widely used for evaluating smoke generation characteristics of materials, including:

(1) Railway materials and components – interior panels, cable insulation, flooring materials

(2) Building materials – wall coverings, ceiling materials, insulation boards

(3) Polymeric materials – plastics, rubber, composites

(4) Electrical and electronic products – housings, enclosures, insulation materials

(5) Transportation materials – automotive and marine interior materials

(6) Fire research and testing laboratories – smoke density and visibility assessment

(7) Smoke toxicity combined testing – used together with gas analysis or FTIR systems

Standards

The instrument complies with the following international standards:

(1) ISO 5659-2 – Plastics — Smoke generation — Part 2: Determination of optical density by a single-chamber test

(2) CEN/TS 45545-2 – Railway applications — Fire protection on railway vehicles — Part 2: Requirements for fire behavior of materials and components

Features

(1) Fully sealed, corrosion-resistant test chamber

(2) Ceramic-lined inner surface with insulated core and galvanized external structure

(3) Observation window integrated into the chamber door for safe test monitoring

(4) Stainless steel sample holder, size 75 × 75 mm

(5) Truncated conical radiant furnace with internal electric heating elements

(6) Adjustable radiant heat flux from 25 to 50 kW/m²

(7) Fuzzy logic temperature control with stability of ±0.01 °C

(8) High-precision Schmidt-Boelter type radiometer with NIST calibration certificate

(9) PC-based data acquisition, processing, and reporting software

(10) Compatible with auxiliary smoke toxicity and gas analysis equipment

Technical Parameters

| Item | Specification |

|---|---|

| External Dimensions (W × D × H) | 1000 × 635 × 2080 mm |

| Internal Chamber Dimensions (W × D × H) | 914 × 610 × 914 mm |

| Weight | Approx. 55 kg |

| Radiant Heat Flux Range | 10 – 50 kW/m² |

| Radiant Furnace Type | Truncated conical, electric heating |

| Radiometer Type | Schmidt-Boelter, 50 kW/m² |

| Radiometer Certification | NIST calibrated |

| Sample Holder Size | 75 × 75 mm (stainless steel) |

| Load Cell Capacity | 3000 g |

| Load Cell Accuracy | ±0.1 g |

| Load Cell Precision | ±0.03 % |

| Power Supply | 230 V, 800 VA |

| Air Supply Requirement | Dry, filtered air, 3 bar |

| Gas Supply | Propane, 0.5 bar |

FAQ

(1) What is this product?

It is a laboratory instrument used to measure the specific optical density of smoke generated by solid materials under controlled fire exposure.

(2) What is this product used for?

It evaluates smoke generation and visibility reduction caused by materials during fire conditions.

(3) Why is this product important?

Smoke density is a key factor affecting evacuation safety and fire hazard assessment, especially in enclosed spaces.

(4) What products can be tested with this instrument?

Railway materials, plastics, building materials, cable insulation, composites, and electronic housings.

(5) What standards does it comply with?

ISO 5659-2 and CEN/TS 45545-2.

(6) How is the test performed?

A vertically mounted specimen is exposed to controlled radiant heat, smoke is generated, and optical transmittance is continuously measured to calculate specific optical density.

Leave Message Get Price