Chemical Reactor Cleaning Systems

Total Chemical Reactor Cleaning Systems

Reactor Cleaning Systems are designed to safely and effectively peel and clean scale stuck to the inside of polymerization tanks, reactors, and storage tanks by using high-pressure water. We design and manufacture all the relevant items for the system such as high-pressure pump, cleaning device, nozzle, and controller etc.

Because of various complex structures such as agitator shaft, it has always been a difficult point in the industry to realize cleaning without dead angle. Due to the following disadvantages of manual cleaning, the cleaning effect can not meet the requirements well all the time:

① Manual operation requires hand-held cleaning, which has the characteristics of high labor intensity, long cleaning time and bad working environment;

② Due to various production processes, there may be toxic or harmful gases in the reactor, which will cause great damage to human body, and even affect human body when cleaning with cleaning solution;

③ The inside of the reactor may be a flammable and explosive working environment, so manual cleaning is dangerous;

④ Because the cleaning method is man-made, the cleaning effect may be greatly affected by human factors;

⑤ Every year, there are reports of casualties in manual cleaning, which has a great impact on the enterprise society and has a great hidden danger;

⑥ Because the reactor generally has mixing shaft, mixing blade, coil, stiffener and other heterogeneous parts, manual cleaning is also difficult

⑦ Because some materials in the reactor are easy to dry and form film, which makes it difficult to clean, the cleaning time is particularly important after the materials in the reactor are emptied.

Working principle of Reactor Cleaning Systems:

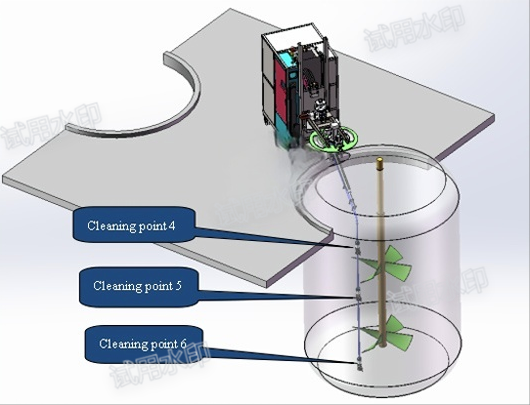

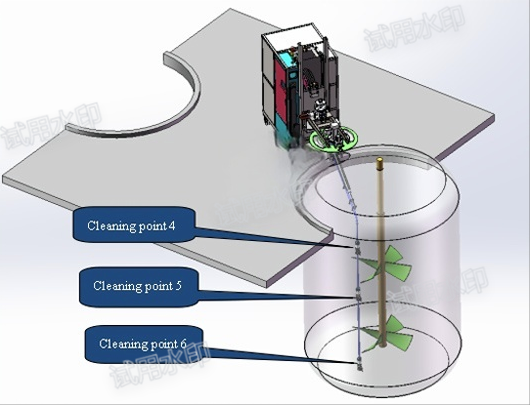

The setting degree of the system can realize one key operation and high automation degree. The automatic reactor cleaning equipment can clean the parts that are difficult to clean, such as the back, bottom and upper head of the mixing shaft. The high pressure water jet is ejected from the high pressure tank cleaning nozzle to realize the cleaning of this position. Generally, 2-4 cleaning points (which can be set by themselves and adjusted according to the actual situation) are set on the mixing shaft after cleaning one side of the mixing shaft. The pipe coiler is recovered to the original point, and then the arm is swing to the other side of the mixing shaft. The same cleaning method as on the left side sets different cleaning points according to the actual needs, and automatic fixed-point cleaning. Each cleaning point can set the cleaning time as required.

Because there are generally various components such as agitator shaft, agitator blade or coil in the reactor, the cleaning without dead angle can only be realized by fixed-point cleaning for cleaning dead point.

The mobile reactor high-pressure cleaning system starts the high-pressure pump after the set cleaning point, and cleans the head by using the high-pressure rotating three-dimensional cleaning. Start to clean the first cleaning point, and set 4-6 points for normal reactor cleaning (fixed point can clean the number of PLC set points for different reactors).

Leave Message Get Price