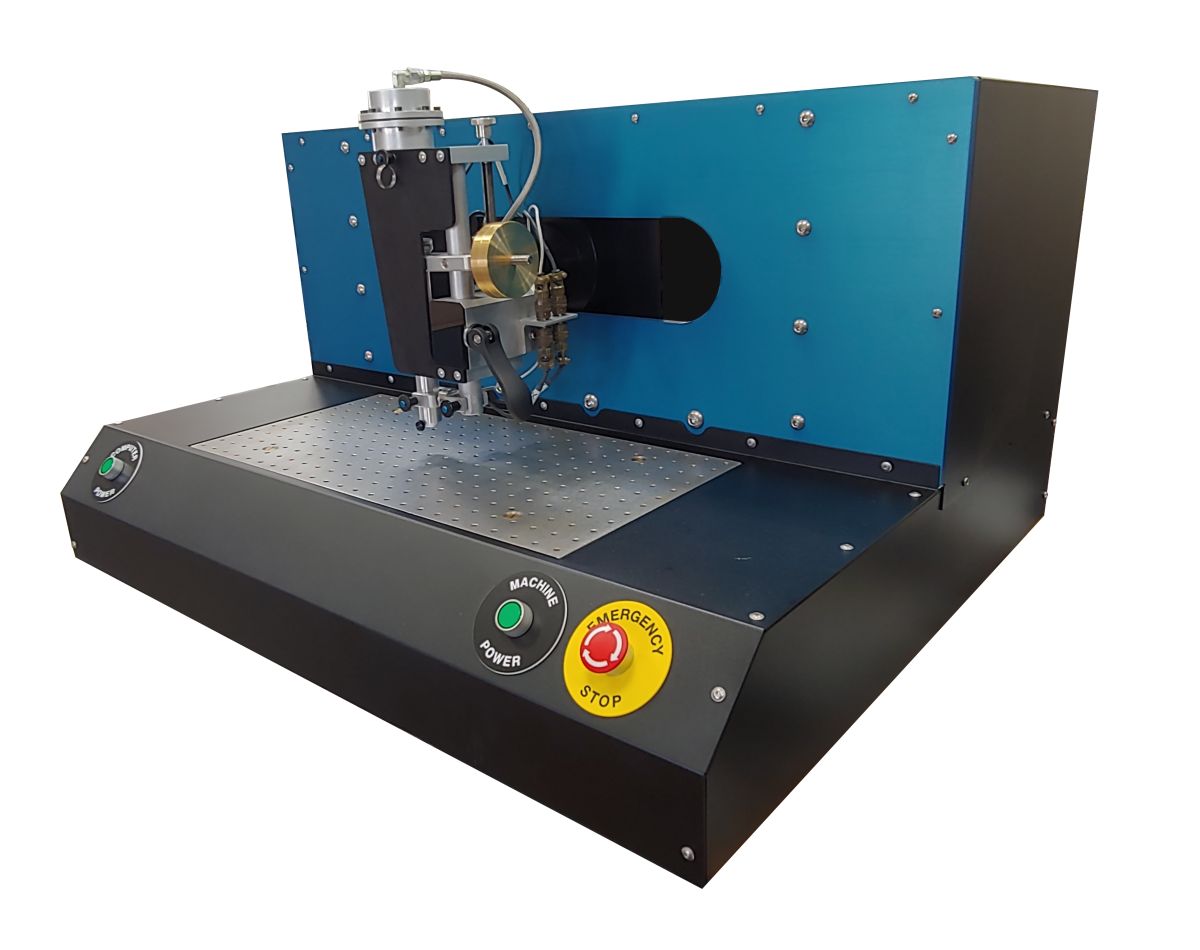

Stud welding torch guard

Product advantages:

Anti splash,High tempera,Flame retarda,Oil repellent;

Design advantage:

Digital remote design,No field measurement required,Short supply cycle,High precision design,Only 2D & 3D digital analog, on-site video and pipeline trend are required.;

Application industry:

Automobile,Shipbuilding,Sheet metal ,Electronics ind,Communication, Instrument,Spare parts;

User pain point:

Existing Problems:High temperature welding slag,Welding slag accumulation,Spatter of welding slag,noise;

User loss:Aging of welding torch,line down,High maintenance costs,Hidden danger;

Product Introduction:

It is made of flame-retardant halogen-free coating fabric and other flame-retardant auxiliary materials.

It can prevent the main body and circuit of stud welding gun from being damaged by high temperature welding slag, and has the characteristics of full body flame retardant, anti welding slag splashing, high temperature resistance, wear resistance and so on.

It can be used in automobile manufacturing enterprises, such as body (welding) workshop, ship manufacturing and other industries using stud welding gun. It can be customized for various models of various brands.

Material parameters:

High performance flame retardant fabric:

We independently developed a number of flame-retardant metal coating fabrics with different prices for customers with different budgets. The flame-retardant properties have reached B1 level. The base cloth is flame-retardant fiber, high temperature resistance, high specific strength and good bending resistance, which can withstand more than 10000 times of friction and meet the high frequency working strength of welding gun. Halogen free metal coating is oil repellent and meets ROHS standard.

High performance flame retardant rubber sheet:

The patented material developed independently, including base cloth and double-sided dip adhesive, can effectively reduce the impact of welding slag splashing, reduce welding slag accumulation, and achieve the flame retardant level of V-0.

Flame retardant Velcro:

The flammability of the buckle burr is up to Class B1, and the tear resistance is good.

Flame retardant sewing thread:

The suture is made of Kevlar 1414 fiber, which has high strength and good toughness, and the ultimate oxygen index is more than 28. It can effectively enhance the suture strength and the flame retardancy of the suture.

| Weight (g/m²) | After-flame Time (s) | After-glow Time (s) | After-glow Length (mm) | Anti-twist and Bending Performance | Tear Strength (N) | Breaking Strength (N) |

| 483.8 | 0 | 0.9 | 33 | Grade 0 | 105 | 2100 |

| 660.5 | 0 | 1.6 | 32 | Grade 2 | 276 | 2100 |

Product details:

Flame retardant rubber sheet:Flame retardant rubber plate is added at the arm of welding gun to effectively resist the front impact of welding slag.

Tail button:Add the daughter and mother buttons at the tail of the welding gun to facilitate the fixation of the protective cover and prevent the welding slag from entering the gun body.

Leave Message Get Price