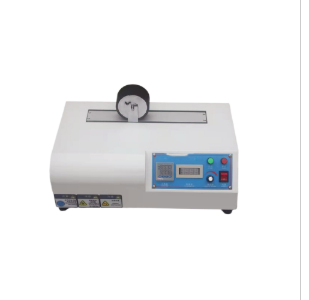

Electronic Roll Testing Machine

The electronic rolling press tester is a professional device used to test the mechanical properties of materials. The following is a detailed description of its main uses, compliance standards, and technical parameters:

I. Main Uses

The electronic rolling press tester has a wide range of application fields, mainly used in the following aspects: - **Peeling Test**: It can assist in various peeling tests to evaluate the mechanical performance of materials during the peeling process. - **Printing Ink Layer Bonding Fastness Test**: It is an important device in the quality inspection of printed products, used to test the bonding fastness between the printing ink layer and the substrate, ensuring the quality of printed products. - **Adhesive Tape Tack Test**: It can test the tackiness of adhesive tapes and evaluate the adhesive performance of adhesive tapes under various conditions. - **Material Mechanical Property Evaluation**: It is used to test the mechanical properties of materials such as hardness, plasticity, and tensile properties, providing data support for material design, manufacturing, and optimization.

II. Compliance Standards

- GB/T 7707: This is a Chinese national standard that details the technical requirements and test methods of electronic rolling press testers.

- GB 2792: Another important Chinese national standard that provides detailed regulations for the adhesion testing of products such as adhesive tapes. - JIS C2107, JIS Z0237: These are Japanese industrial standards that also specify the relevant test methods for electronic rolling press testers.

III. Technical Parameters

- **Rolling Speed**: Usually adjustable within the range of 10 - 1000mm/min, and the specific speed can be set according to test requirements. The rolling speed of some devices may be lower or higher, such as 300mm/min or can reach a higher maximum speed. - **Roller Load**: Generally, it is 20N±0.5N, but there are also other customizable weight options to meet different test requirements. - **Rolling Times**: It can be set within the range of 0 - 999 times, and some devices may have a larger setting range. - **Rolling Distance**: Usually adjustable within the range of 0 - 200mm, and the specific distance can also be set according to test requirements. - **Overall Dimensions and Weight**: The overall dimensions and weight of the device may vary depending on the model and brand, but it is generally compact and easy to operate. - **Environmental Requirements**: Usually, the ambient temperature is required to be within the range of 15°C - 35°C (or 15°C - 50°C), the relative humidity should not exceed 80%, and there should be no condensation. Meanwhile, the device needs to be connected to a 220V, 50Hz power supply for operation.

Leave Message Get Price