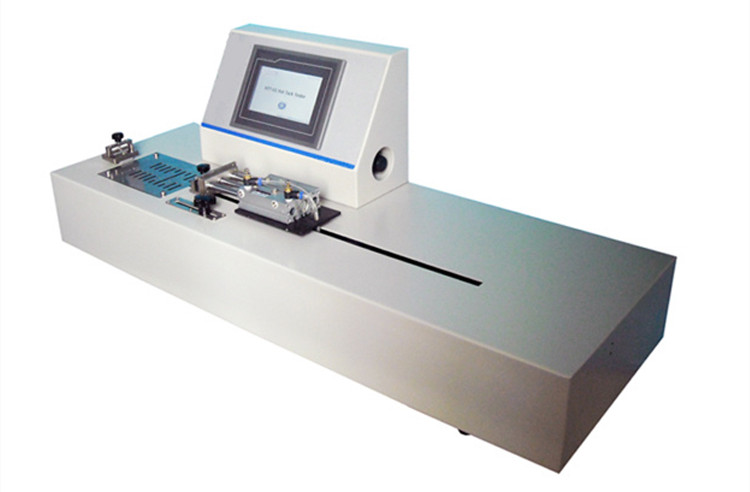

Thermal viscosity tester

Applicable standards:

QB/T 2358 (ZBY 28004) : This standard provides detailed technical requirements and test methods for specific types of thermal viscosity tester.

ASTM F2029: A standard published by the American Society for Materials and Testing (ASTM) specifically for heat seal testing, which includes test requirements for thermal adhesion.

YBB 00122003: May be a standard for pharmaceutical packaging materials in a particular field or country that contains provisions for thermal viscosity testing.

ASTM F1921: Another standard published by the American Society for Materials and Testing, related to the thermal viscosity test of thermoplastic polymers.

ASTM F88: This is a standard for thermal sealing strength testing of barrier flexible packaging materials, and although it is primarily concerned with thermal sealing strength, it may also be related to thermal viscosity testing.

Main parameters:

Heat seal temperature: usually room temperature to 350 ° C (or 250 ° C), used to set the temperature of the heating element to meet the thermal adhesion test needs of different materials. Accuracy is usually between ±0.1 ° C and ±0.7 ° C.

Heat sealing time: The control range of heat sealing time is usually between 0.01 seconds and 99.99 seconds, which can precisely control the heating time to adapt to the thermal bonding process of different materials.

Heat seal pressure: The heat seal pressure is controlled from 0.05MPa to 0.7MPa (or 137.9Kpa to 2758Kpa) and is used to apply the necessary pressure to promote the thermal adhesion of the material.

Heat sealing area: refers to the area of contact between the heating element and the material to be tested, usually with a standard size range, such as 170mm×10mm.

Test force range: The test force range may vary from device to device, but is usually sufficient to cover the thermal bonding strength test needs of common materials. For example, some devices may have a test force range of 0 to 1.2N (or 0 to 4448.2N)。

Sensitivity and accuracy: The sensitivity and accuracy of the equipment are critical to the accuracy of the test results. Sensitivity usually refers to the ability of the device to respond to small changes, while accuracy refers to how close the test result is to the actual value.

Leave Message Get Price