Building material combustion calorific value calorimeter

Building material combustion calorific value calorimeter Mainly used for the detection of stone, wood, concrete, evenly dispersed mineral wool and polymers and other building materials, the determination of calorific value of fuels, used in building research and technical supervision and other departments.

Standards compliant:

GB / T 14402-2007 "Combustion properties of building materials and articles - Determination of combustion calorific value"

Building materials burning calorific value tester / building materials burning calorific value detector

Main features:

1. This equipment is in the same kind of pre-product developed on the basis of a new type of analytical instruments;

2. Using high-end single-chip, large-screen LCD screen, the entire Chinese user interface;

3. Has a high precision measurement, small size, easy operation, automatic ignition, automatic water, water, mixing, calculation, printing and other characteristics;

4. It is one of the test methods to evaluate whether the combustion performance meets Grade A composite (sandwich) materials is used to determine the total calorific value and the net calorific value.

Building material combustion calorific value calorimeter Test principle:

Under standard conditions, a specific mass of the sample is placed in a constant volume of oxygen and nitrogen calorimeter, the test sample combustion calorific value of the equipment, under standard conditions, the test to test the temperature based on the consideration of all heat Loss, and latent heat of vaporization, calculate the combustion calorific value of the sample.

Building materials burning calorific value tester / building materials combustion calorific value detector Main parameters:

1. Measurement principle: Oxygen bomb heat method

2. Measurement time: (30-60) min

3. Temperature resolution: 0.001 ℃

4. Ignition method: short circuit ignition

5. Ignition time: 5s

6. Ignition voltage: DC12V

7. Outside the water tank capacity: about 40L

8. Internal water tank capacity: about 2.1L

9. Test environment: (23 ± 2) ℃ (per room temperature change should be ≤ 1 ℃) Relative humidity (40-60)% RH

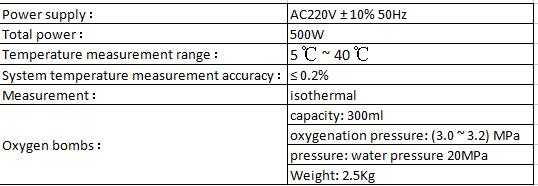

Accessories parameters:

Leave Message Get Price