Intervertebral Fusion Cage Compression Fatigue Tester

Standards:

ASTM F2077

ASTM F2267

Main applications:

Performance evaluation: Test the fatigue strength, stiffness, deformation, and other mechanical properties of intervertebral fusion cages under compression loads to assess their overall performance and ability to withstand the cumulative effects of cyclic compressive stress over time. This helps determine if the cage can maintain its structural integrity and height under repeated loading without catastrophic failure or significant plastic deformation (subsidence).

Quality control: During the production process, use the compression fatigue testing machine to conduct quality inspections on intervertebral fusion cages. By subjecting samples from each manufacturing batch to compression fatigue testing according to established criteria, manufacturers can ensure that the products consistently meet the predetermined performance standards for fatigue resistance, thereby reducing the defective rate and ensuring product reliability.

R & D support: Provide experimental data support for the research and development of intervertebral fusion cages. Testing different cage designs (e.g., variations in geometry, pore size, endplate design), materials (e.g., PEEK, titanium alloys, novel porous materials), and manufacturing processes under compression fatigue assists R&D personnel in optimizing these factors to improve the cage's durability, load-bearing capacity, and long-term stability within the spinal segment.

Product Advantages:

The Intervertebral Fusion Cage Compression Fatigue Tester offers significant advantages for evaluating the critical compressive fatigue performance of these implants:

Simulates Primary Spinal Loading: Focuses on the dominant compressive forces experienced by fusion cages in the spine, providing highly relevant fatigue data.

Determines Fatigue Life Under Compression: Provides quantitative data on the number of cycles to failure under specific compressive load levels, essential for predicting implant longevity and preventing subsidence.

Critical for Patient Safety: Contributes directly to ensuring the long-term mechanical integrity of the implant, reducing the risk of cage fracture or collapse in vivo.

Supports Regulatory Compliance: Enables testing according to standards like ASTM F2077. which is often required for obtaining regulatory approval for intervertebral body fusion devices.

Objective Performance Data: Yields precise, objective measurements of fatigue strength, stiffness degradation, and deformation under cyclic compression, allowing for clear comparison of different cage designs and materials.

Facilitates R&D and Quality Control: An indispensable tool for developing improved cage designs and materials and for maintaining consistent manufacturing quality.

Product Features:

An Intervertebral Fusion Cage Compression Fatigue Tester is typically a dynamic testing system specifically configured for applying controlled cyclic compressive loads to fusion cages. Key features include:

A dynamic testing frame (e.g., servo-hydraulic or electrodynamic) with a high stiffness and capacity suitable for applying physiological compressive loads encountered in the spine.

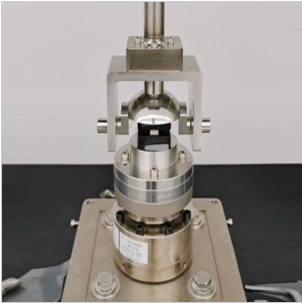

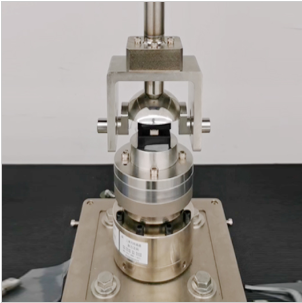

A specialized fixture designed to hold the intervertebral fusion cage and apply cyclic compressive loads. This fixture typically utilizes simulated vertebral body blocks (often made from a rigid polymer or bone substitute material, or sometimes using actual bone) with geometries matching the cage endplates, between which the cage is placed and compressed.

A dynamic load cell for accurate measurement of the applied cyclic compressive force.

A displacement sensor or the testing machine's measurement system to record the axial deformation (subsidence) of the cage assembly under cyclic loading.

A control system capable of applying cyclic compressive loading profiles (e.g., sinusoidal, haversine, mimicking physiological loading) at specified frequencies and load or displacement amplitudes.

A cycle counter to accurately record the total number of load cycles applied.

A data acquisition system to capture load, displacement, and cycle count data throughout the fatigue test.

Sophisticated software for setting up fatigue test parameters, real-time monitoring of test progress, detecting sample failure (e.g., fracture, excessive subsidence), and analyzing fatigue data (e.g., generating S-N curves, evaluating stiffness and subsidence over cycles).

An environmental chamber or fluid bath designed to enclose the test setup, capable of maintaining physiological temperature (e.g., 37°C) and holding a simulated body fluid (e.g., saline solution) to replicate the in vivo environment.

Safety features such as overload protection and automatic shutdown upon specimen failure.

Technical Parameters:

Frequency Range: (e.g., up to 10 Hz, 20 Hz, or higher, as specified by the relevant testing standard, e.g., ASTM F2077. typically 5 Hz)

Load Control Accuracy: (e.g., ±1% of set load or better)

Displacement Control Accuracy: (e.g., ±1% of set displacement or better)

Type of Loading: (Axial Compression, with load or displacement control)

Maximum Number of Cycles: (Designed for long-term testing, e.g., up to 5 million or 10 million cycles as per standards like ASTM F2077)

Actuator Stroke: (Sufficient to apply required displacements under cyclic compression)

Environmental Chamber/Fluid Bath Temperature Range: (e.g., Ambient to 40°C or higher, with precise control around 37°C)

Environmental Chamber/Fluid Bath Temperature Accuracy: (e.g., ±1°C or ±0.5°C)

Sample Size Capacity: (Able to accommodate the dimensions of various intervertebral fusion cage designs and sizes)

Power Supply: (e.g., AC 220V or 380V, 50/60 Hz, potentially with a hydraulic power unit if servo-hydraulic)

Leave Message Get Price