Bone Cement Bending Fatigue Tester

Standards:

ASTM F2118

ISO 16402

Application:

Evaluate the bending fatigue performance of bone cement materials under simulated human physiological environments. By applying cyclic bending loads to bone cement specimens while they are immersed in a temperature-controlled fluid (such as saline or simulated body fluid) at approximately 37°C, the tester simulates the conditions experienced by bone cement in the body. This provides crucial data on how the material behaves under realistic loading and environmental conditions over time.

Study the influence of different formulations and preparation processes on the bending fatigue performance of bone cement. Researchers and manufacturers can use this tester to compare the fatigue life of bone cement prepared with varying powder-to-liquid ratios, mixing methods, or containing different additives (e.g., antibiotics, radiopacifiers). This helps optimize material composition and handling protocols for improved fatigue resistance.

Compare the differences in bending fatigue performance among bone cement materials from different brands and models. The tester provides a standardized method for objectively comparing the fatigue durability of commercially available bone cements, assisting surgeons and hospitals in selecting appropriate materials for specific clinical applications.

Provide scientific evidence and references for the application of bone cement materials. The data generated from bending fatigue tests is essential for regulatory submissions (e.g., to FDA or equivalent bodies) to demonstrate the mechanical properties and long-term durability of bone cement. It also contributes to the scientific literature, supporting the safe and effective use of bone cement in orthopedic procedures.

Product Advantages:

The Bone Cement Bending Fatigue Tester offers significant advantages for characterizing the critical fatigue properties of bone cement:

Simulates In Vivo Conditions: Enables fatigue testing in a simulated physiological environment (temperature and fluid), providing more clinically relevant data than tests in ambient air.

Quantitative Fatigue Life Data: Provides objective, measurable data on the number of cycles to failure at specific load levels, essential for predicting material longevity.

Supports Material Development: Crucial for researchers developing new bone cement formulations with enhanced fatigue resistance.

Essential for Quality Control: Allows manufacturers to ensure consistency in the fatigue performance of their product batches.

Facilitates Product Comparison: Provides a standardized method for comparing the performance of different bone cement products.

Aids Regulatory Approval: Generates necessary data to support the safety and efficacy claims of bone cement materials for regulatory bodies.

Product Features:

A typical Bone Cement Bending Fatigue Tester is configured around a dynamic testing system and includes features specifically designed for testing bone cement specimens:

A dynamic testing frame (e.g., servo-hydraulic or electrodynamic) capable of applying precise cyclic loads (force or displacement) in a bending configuration.

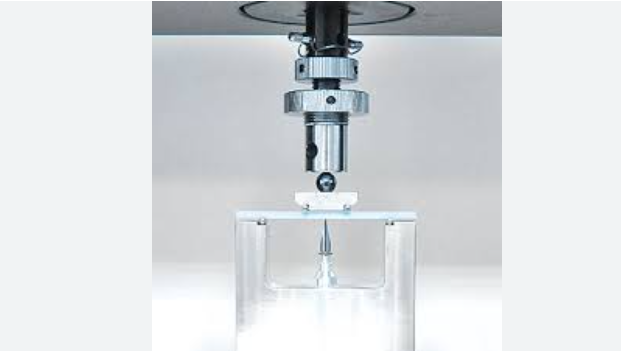

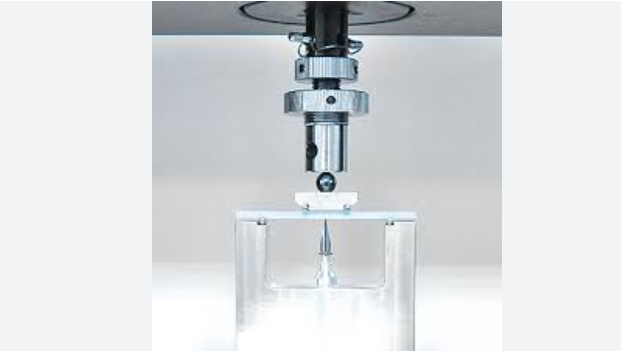

A bending fixture suitable for bone cement specimens, often a three-point or four-point bending setup, with adjustable spans to accommodate standard specimen geometries (e.g., as specified in ASTM F2118 or ISO 16402).

A dynamic load cell for accurate measurement of the applied cyclic bending force.

A displacement sensor or the testing machine's displacement measurement system to monitor specimen deflection during testing.

A control system capable of applying various cyclic waveforms (e.g., sinusoidal, haversine) at specified frequencies and load/displacement amplitudes.

A cycle counter to accurately record the number of load cycles applied to the specimen.

A data acquisition system to capture load, displacement, and cycle count data throughout the fatigue test.

Sophisticated software for setting up fatigue test parameters, monitoring test progress, detecting specimen failure, and analyzing fatigue data (e.g., creating S-N curves).

An environmental chamber or fluid bath designed to enclose the specimen and bending fixture, capable of maintaining a constant temperature (typically 37°C) and holding a simulated body fluid.5

Heating and temperature control system for the environmental chamber or fluid bath.

Safety features such as overload protection and automatic shutdown upon specimen failure.

Fixturing or methods for securely mounting bone cement specimens within the bending fixture.

Technical Parameters:

Dynamic Load Capacity: (e.g., typically ranging from ±0.5 kN to ±10 kN, depending on the strength of the bone cement and specimen geometry)

Frequency Range: (e.g., up to 10 Hz, 20 Hz, or higher, as specified by the relevant testing standard)

Load Control Accuracy: (e.g., ±1% of set load or better)

Displacement Control Accuracy: (e.g., ±1% of set displacement or better)

Type of Bending: (Three-point or Four-point, depending on the fixture and standard)

Bending Fixture Span: (Adjustable range to accommodate standard bone cement specimen lengths, e.g., as specified in ASTM F2118 or ISO 16402)

Maximum Number of Cycles: (Designed for long-term testing, e.g., up to 5 million or 10 million cycles as per standards)

Environmental Chamber/Fluid Bath Temperature Range: (e.g., Ambient to 40°C or higher, with precise control around 37°C)

Environmental Chamber/Fluid Bath Temperature Accuracy: (e.g., ±1°C or ±0.5°C)

Sample Size/Geometry Capacity: (Designed to accommodate standard bone cement fatigue specimens, often dumbbell-shaped or beam-shaped)

Power Supply: (e.g., AC 220V or 380V, 50/60 Hz, potentially with a hydraulic power unit if servo-hydraulic)

Leave Message Get Price