Absorbable Bone Plate Four-Point Bend Tester

Standard:

ASTM F382

ASTM F2502

ISO 9585

Product Introduction

This tester is specifically designed for conducting four-point bending tests on absorbable bone plates. Four-point bending is a preferred method for testing bone plates as it produces a region of uniform bending moment between the inner loading points, which simplifies stress calculations and is representative of how plates are loaded in situ. The main applications of this tester include:

Evaluating mechanical properties: Through four-point bending tests, the bending behavior of bone-connecting plates under different loads can be measured, including key parameters such as maximum load-bearing capacity, elastic modulus (bending stiffness), and maximum deflection before fracture.

Studying the failure mechanism: Observe and analyze characteristics such as the deformation, crack initiation and propagation of bone-connecting plates during the bending test process to study the failure mechanism and provide a basis for optimizing the design of absorbable bone plates for improved performance and predictable degradation.

Quality control: During the production process, four-point bending performance tests can be carried out on absorbable bone-connecting plates to ensure that they meet the predetermined performance standards and requirements, improving product quality and ensuring consistency between manufacturing batches.

Scientific research and teaching: This tester can also be used in teaching and scientific research activities in scientific research institutions and universities, providing students with practical opportunities to understand biomaterial mechanical testing and providing an experimental platform for researchers developing new absorbable implant materials and designs.

Product Advantages:

The Absorbable Bone Plate Four-Point Bend Tester offers several advantages for evaluating these critical medical devices:

Accurate Simulation of Loading: Four-point bending closely simulates the bending loads experienced by bone plates when implanted in the body.

Quantitative Mechanical Data: Provides precise, objective measurements of key mechanical properties essential for design validation and regulatory submission.

Failure Analysis Capabilities: Allows for detailed observation and analysis of failure modes under controlled bending stress.

Supports Regulatory Compliance: Enables testing according to relevant ASTM and ISO standards required by regulatory bodies for medical devices.

Objective Quality Assessment: Provides a standardized method for quality control to ensure consistent product performance.

Versatility for Research: Useful for comparing different materials, designs, and manufacturing processes of absorbable bone plates.

Product Features:

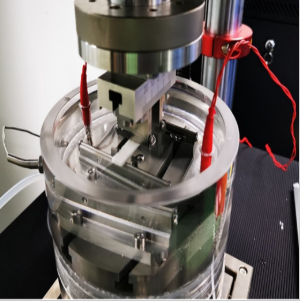

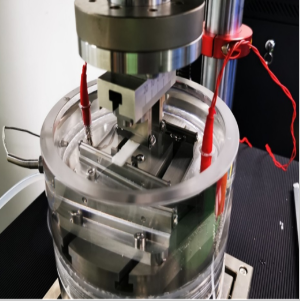

A typical Absorbable Bone Plate Four-Point Bend Tester is configured around a universal testing machine frame or a dedicated bending test system and includes the following features:

A robust testing frame capable of applying controlled forces in a bending configuration.

A four-point bending fixture consisting of two lower support anvils and two upper loading anvils.

Adjustable spans for both the inner loading anvils and the outer support anvils to accommodate different bone plate lengths and testing standard requirements.

A load cell to accurately measure the applied bending force.

A displacement sensor or extensometer to measure the deflection of the bone plate under load.

Precise motion control for applying load or displacement at controlled rates (for static tests) or for cyclic loading (for fatigue tests, if applicable).

Data acquisition system to record load and displacement data throughout the test.

Software for controlling the test, collecting data, calculating mechanical properties (e.g., bending strength, stiffness), and generating test reports.

Sample fixturing designed to securely hold bone plates of various geometries without introducing unwanted stresses.

Technical Parameters:

Load Capacity: (e.g., typically ranging from 1 kN to 20 kN or more, depending on the expected strength of the plates tested)

Displacement Measurement Range: (Sufficient to measure deflection up to sample fracture)

Accuracy of Load Measurement: (e.g., ±1% of reading or better)

Accuracy of Displacement Measurement: (e.g., ±1% of reading or better)

Adjustable Inner Span (Loading Anvils): (e.g., range covering relevant bone plate lengths)

Adjustable Outer Span (Support Anvils): (e.g., range covering relevant bone plate lengths and standard requirements)

Testing Speed Range: (e.g., 0.01 mm/min to 500 mm/min for static tests, specific frequencies for fatigue tests)

Sample Size Capacity: (Able to accommodate the dimensions of typical bone plates)

Power Supply: (e.g., AC 220V or 380V, 50/60 Hz)

Leave Message Get Price