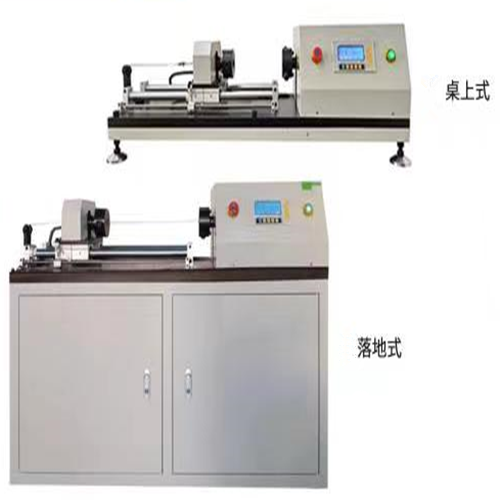

Metal Wire Torsion Tester

Applicable standards:

GB/T 239.1-2012 "Metal materials wire Part I unidirectional torsion test method"

GB/T 239.2-2012 "Metal materials wire Part II Bidirectional torsion test method"

ISO 7800:2003 "Test method for unidirectional torsion of metal wires"

ISO 9649:1990 Test method for bidirectional torsion of metal wires

Test principle:

Unidirectional torsion: The sample rotates 360 degrees evenly around its axis in one direction as a single torsion to the specified number of times or the sample breaks.

Two-way torsion: the sample rotates 360 degrees evenly around its axis in one direction as a torsion to the specified number of times, and then rotates the same number of times in the opposite direction or the sample breaks.

Product Advantages:

The Metal Wire Torsion Tester offers several advantages for reliable metal wire evaluation:

Compliance with Standards: Designed to meet recognized national and international torsion testing standards, ensuring the validity and comparability of test results.

Unidirectional and Bidirectional Testing: Capable of performing both types of torsion tests as required by different standards and material specifications.

Objective Evaluation: Provides a quantitative measure of the number of twists to failure or the ability to withstand a specified number of twists, offering objective data on wire quality.

Reveals Material Defects: The torsional stress highlights surface cracks, internal flaws, and inconsistencies that might not be detectable by other tests.

Precise Speed Control: Allows for accurate control of the twisting speed as specified by the testing standards.

Product Features:

The tester incorporates features necessary to perform accurate and controlled metal wire torsion tests:

A sturdy horizontal frame with two clamping fixtures (grips) to hold the wire sample securely at both ends.

One fixed grip that prevents rotation of one end of the sample.

A rotating grip, typically motorized, capable of twisting the other end of the sample around its axis.

Adjustable distance between the two fixtures to accommodate different sample lengths.

A motor with precise speed control to achieve the required twisting speed (e.g., 30 or 60 r/min).

A counter to automatically record the number of 360-degree twists (torsions) applied to the sample.

An automatic stop mechanism that halts the motor when the sample breaks or reaches a preset number of twists.

(For bidirectional testing) The capability for the rotating grip to reverse direction accurately after completing the specified number of turns in one direction.

Main parameters:

1, clamping metal wire diameter range: 3.0≤d(D)<5.0

2, the space between the two fixtures: 500mm

3. Clamp range: 3.0-5.0mm

4, twisting speed: 30, 60r/min

5. Power supply: AC220V 50Hz

6, Noise: <70 dB(A)

Leave Message Get Price