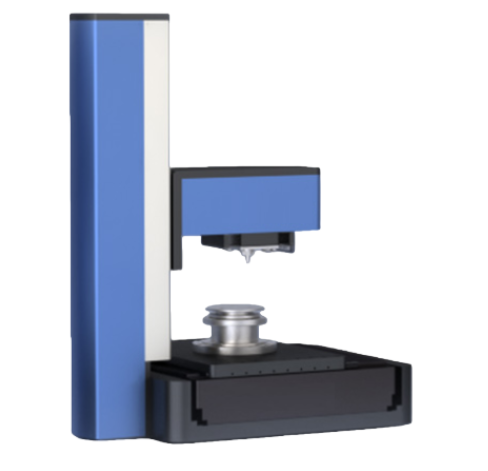

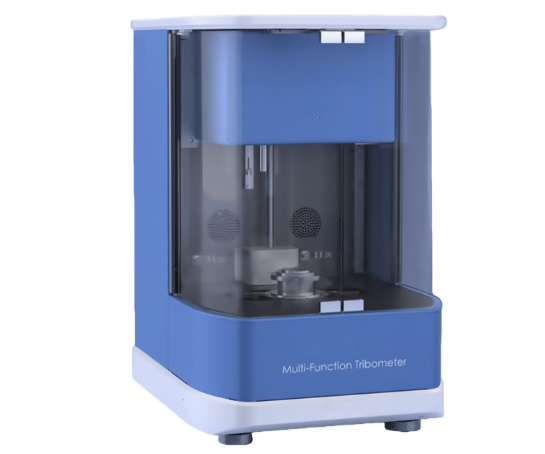

KES - NDG5 Puncture Strength Tester

### Introduction to the Device This device is a testing machine used to measure the "puncture strength" when a sample is penetrated by a test needle. As a physical test for battery separators, it can measure the breaking strength of the force applied in the vertical direction. It can be used for evaluating the strength of the separators (isolation membranes) inside lithium - ion batteries and testing the puncture strength of packaging materials such as food packaging films. ### Features This tester can only measure the puncture strength when the sample is pierced by a needle. The breaking strength under the force in the vertical direction is one of the physical test methods for battery separators, which can be measured by this tester. ### Technical Requirements 1. **Measurement environment temperature and humidity**: Temperature 20~30°C, humidity 50~70%RH without condensation (Standard temperature and humidity conditions: Temperature 20°C, humidity 65%RH) 2. **Load detection** - Detector: Differential transformer (ring - type dynamometer) - Load (full - scale range): Four - range switching of 100gf, 200gf, 500gf, and 1000gf - Accuracy: Within ±0.5% of the full - scale range 3. **Displacement detection** - Detector: Potentiometer - Maximum displacement: ±0.5mm - Accuracy: Within ±0.5% of the full - scale range 4. **Special test needle tip**: Designed with consideration for the testing of separators, with a diameter of 1mm and a tip shape of 0.5R 5. **Diameter of the middle through - hole of the sample fixing plate**: 10mm 6. **Displacement speed** - Standard measurement: 0.02(mm/sec) <1mm/50sec> - High - sensitivity measurement: 0.0067(mm/sec) <1mm/150sec>. Other settings can also be made as required. 7. **Measurement modes**: Load control mode and displacement control mode. The above two modes can be switched. 8. **Sample size (standard)**: 15mm×15mm or larger, with a thickness of 1mm or less.

Leave Message Get Price