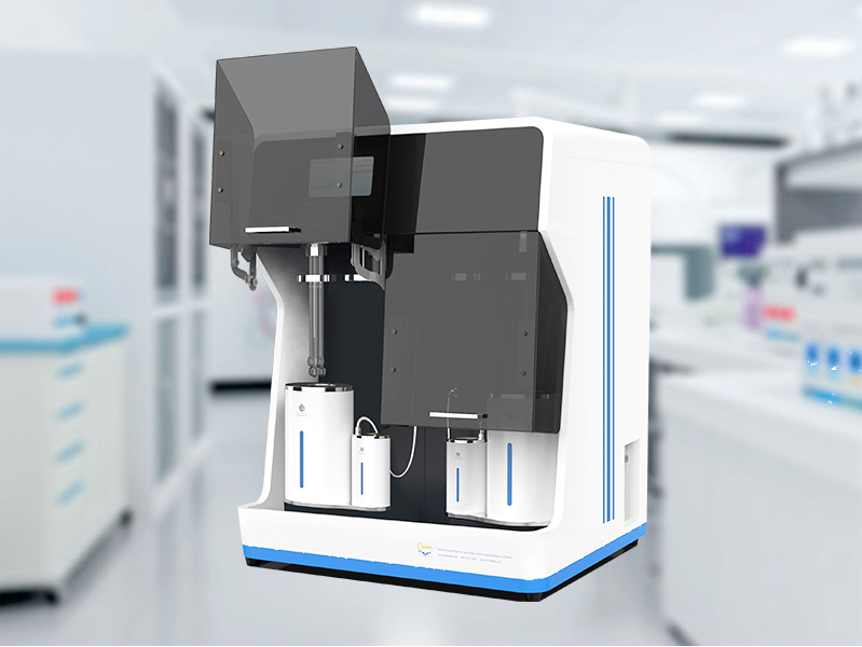

KM-5A Particle Abrasion Tester

The KM-5A particle attrition tester is specially designed according to the test method for the determination of catalyst attrition rate in my country, and applies to the "China Chemical Industry Standard Fertilizer Catalyst Attrition Rate Determination HG/T2976-2011". It is a new generation product launched after the KM-Ⅲ particle attrition tester, with further improved performance and a more reasonable structure. It is widely used in chemical, pharmaceutical, petroleum, and other industries. This instrument uses a single-chip microcomputer to control the stepper motor to drive the grinding drum to rotate and wear the material. Because of the single-chip microcomputer control, its rotation speed is high and the rotation speed is uniform and stable. The working status information of the instrument is indicated by LED light-emitting tubes, which are clear and intuitive. In addition, it also has the functions of presetting the rotation speed, setting alarms, and setting pauses. The instrument has leading technology in China, reasonable structure, simple and intuitive operation, stable and reliable performance, and extremely low failure rate. Therefore, it has a high performance-price ratio and is an ideal wear-rate test device.

Main technical indicators of KM-5A particle wear tester:

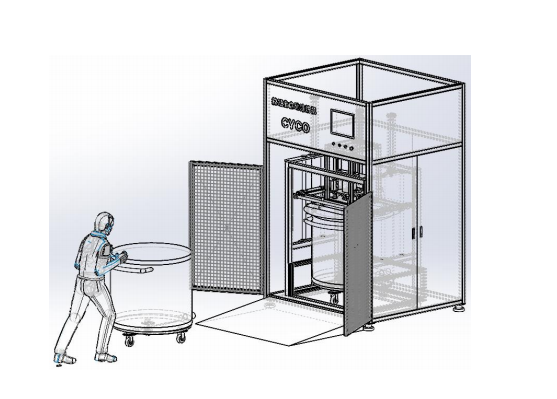

1. Grinding cylinder

Quantity: 2

Grinding cylinder inner diameter: ф120mm

Grinding cylinder length: 150mm.

There is a baffle in the grinding cylinder, 150mm long and 18mm high.

Grinding cylinder rotation speed: 25r/min; 30r/min; 40r/min; 50r/min; 60r/min; (optional setting)

Grinding time: 0-99min (optional setting)

2. Vibrating screen

Sampling screen: one screen with 850μm (20 mesh)

Sieving frequency: 4f/s (1-9 f/s arbitrarily set)

Sieving time: 30s

Leave Message Get Price