Fabric Pilling Tester

The instrument is used to test the pilling conditions of wool fabric, chemical fiber cotton, and blended, knitted, woven fabric to identify product quality and process effect. When testing, the fabric is rubbed against nylon brush and abrasive, or rubbed against abrasive only in the humidity state.

Circular Locus Pilling Tester Standard:

GB/T.1Determination of pilling properties of textile fabrics - Part 1: Circular trajectory method

JIGBell-type gas flow standard device verification procedures

DIN.2Testing of textiles - Wear test of flat fabrics – Roll to mill

Technical Parameters:

1.Contact gap between abrasive assembly and abrasive platform: ≤0.2mm;

2.Parallelism of grinding head and grind plane: ≤0.3mm;

3.Moving locus:¢40mm circle track moving;

4.Nylon brush with paralleled surface, the altitude difference: <0.5mm;

5.Reciprocating speed of abrasive platform: 60±1r/min;

6.Weight of grinding head: 490cN±1%;

7.Weight of larger loading weight/pieces: 290cN±1%;

8.Weight of little loading weight/pieces: 100cN±1%;

9.Times of options: 1~9999;

10.Meet the requirements of standard tests.

Circular Locus Tester Test Reference

|

Sample type |

Pressure / cN |

Number of fluff times |

Number of pilling times |

|

Synthetic fiber knitted fabric |

590 |

150 |

150 |

|

Chemical fiber woven fabric |

590 |

50 |

50 |

|

Military service (combed blended) |

490 |

30 |

50 |

|

Combed wool fabric |

780 |

0 |

600 |

|

Coarse wool fabric |

490 |

0 |

50 |

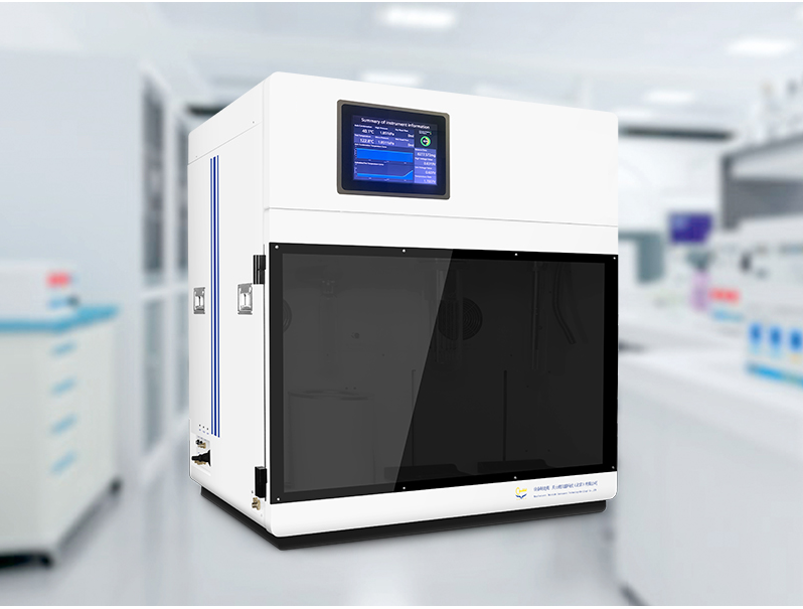

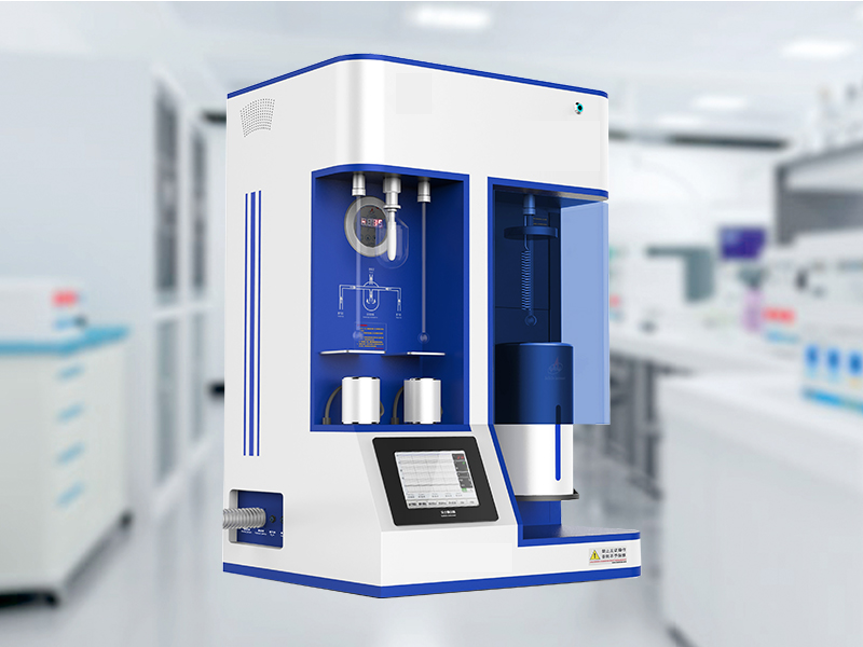

Product Display:

Leave Message Get Price