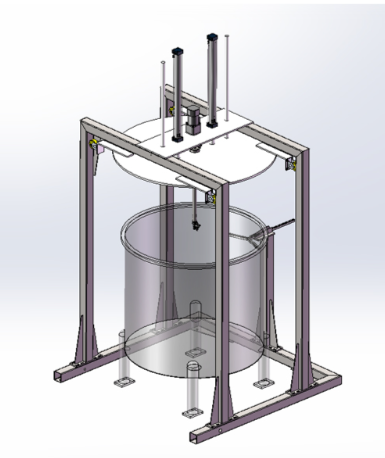

Fractional Efficiency Test Bench

Introduction

Fractional efficiency test bench main structure and trend, important parts configuration, function and important parameter setting, material selection, data processing, test bench main verification project, are based on ISO-19713-1 standard " Road vehicles - Inlet air cleaning equipment for internal combustion engines and compressors - Part 1: Fractional efficiency testing with fine particles ".

Aerosol manufacturing reference to the US standard ANS / ASHRAE 52.2-1999, fixture manufacturing reference to the European standard EN1822.

Application

This type of products is used for clean room supplies production enterprises, filter production enterprises, the relevant scientific research units and measurement of enterprises and other enterprises.

Technical Parameters

Working condition

· Power supply: AC 220V 50Hz Power: 4KVA

· Air supply: compressed air 5-8kg / cm2

· Ambient temperature: 10o -25o RH ≤ 70% Purification grade: 10,000 level

· Covered area: test bench size: operation box 600 * 600 * 1760; sampling box 600 * 600 * 1760; air box generator box 730 * 830 * 2800 (l * w * h) Unit: mm

· Filter material sample size: test bench effective detection area: 100cm2 round

Components

· KCL aerosol generator

· Mixer

· Filter on the next fixture

· Upstream and downstream particle isokinetic sampler

· Upstream and downstream particle counters

· Flow system

· Electrical, computer control system

· Test results output section

Fractional efficiency test bench main structure and trend, important parts configuration, function and important parameter setting, material selection, data processing, test bench main verification project, are based on ISO-19713-1 standard " Road vehicles - Inlet air cleaning equipment for internal combustion engines and compressors - Part 1: Fractional efficiency testing with fine particles ".

Aerosol manufacturing reference to the US standard ANS / ASHRAE 52.2-1999, fixture manufacturing reference to the European standard EN1822.

Application

This type of products is used for clean room supplies production enterprises, filter production enterprises, the relevant scientific research units and measurement of enterprises and other enterprises.

Technical Parameters

| Items | Parameters | |

| Test aerosol | Material | KCL solid particles |

| Particle size | 0.3um-10um | |

| Concentration | adjustable (≥ 10um particle concentration of about 5000-10000J / L | |

| Upstream and downstream particle counter | Sampling Flow | 28.3L / min ± 5% |

| Particle size | 0.3um, 0.5um, 1um, 3um, 5um, 10um | |

| Particle size distribution error | indication concentration error; another count requirements are in line with national JJF 1190-2009 "dust particle counter correction norms" and on this basis, with particular emphasis on large particles (3um, 5um, 10um) metering correction. | |

| Test flow rate | Flow adjustable range | 60L / min-150L / min (equivalent to the filter speed 10cm / s-25cm / s) |

| Flow accuracy | ≤ ± 5% | |

| Flow stability | ≤ ± 10% | |

| Filter resistance measurement | Range | 0-500Pa (Please consult with other areas) |

| Accuracy | ≤ ± 5% | |

| Repeatability | ≤ ± 5% | |

| The initial classification efficiency measurement | Applicable scope | medium,high effect filter material |

| Repeatability | ≤ ± 5% |

Working condition

· Power supply: AC 220V 50Hz Power: 4KVA

· Air supply: compressed air 5-8kg / cm2

· Ambient temperature: 10o -25o RH ≤ 70% Purification grade: 10,000 level

· Covered area: test bench size: operation box 600 * 600 * 1760; sampling box 600 * 600 * 1760; air box generator box 730 * 830 * 2800 (l * w * h) Unit: mm

· Filter material sample size: test bench effective detection area: 100cm2 round

Components

· KCL aerosol generator

· Mixer

· Filter on the next fixture

· Upstream and downstream particle isokinetic sampler

· Upstream and downstream particle counters

· Flow system

· Electrical, computer control system

· Test results output section

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price