Glazed Ceramic Tile Abrasion Tester

I. Main Uses and Applicable Scope

This tester is designed and manufactured in strict accordance with the international standard ISO/DIS 10545-7-1996 "Ceramic Tiles – Surface Wear Resistance Test Method for Glazed Tiles" and the Chinese national standard GB/T 3810.7-2016 "Test Method for Glaze Wear Resistance of Ceramic Tiles". It places a specified amount of abrasive material on the glazed surface of ceramic tiles, grinds the sample under the abrasive, and visually compares the wear differences on the tested glaze surfaces for classification.

II. Main Technical Specifications

Sample Dimensions: 100×100mm; Supports simultaneous testing of 3 or 8 samples (also known as an "eight-head grinder")。 Testing with fewer than 3 or 8 samples is also feasible.

Distance from Center of Supporting Plate to Each Sample: 195 mm; Equal spacing between adjacent sample clamps.

Rated Speed of Supporting Plate: 300 rpm.

Eccentricity: e=22.5mm.

Metal Clamp with Rubber Sealing:

Inner diameter: Φ83mm;

Internal height: 25.5 mm;

Test area per clamp: Approximately 54mm

Motor Power: 0.55 kW.

Power Supply: 380V,50Hz.

III. Main Structure and Working Principle

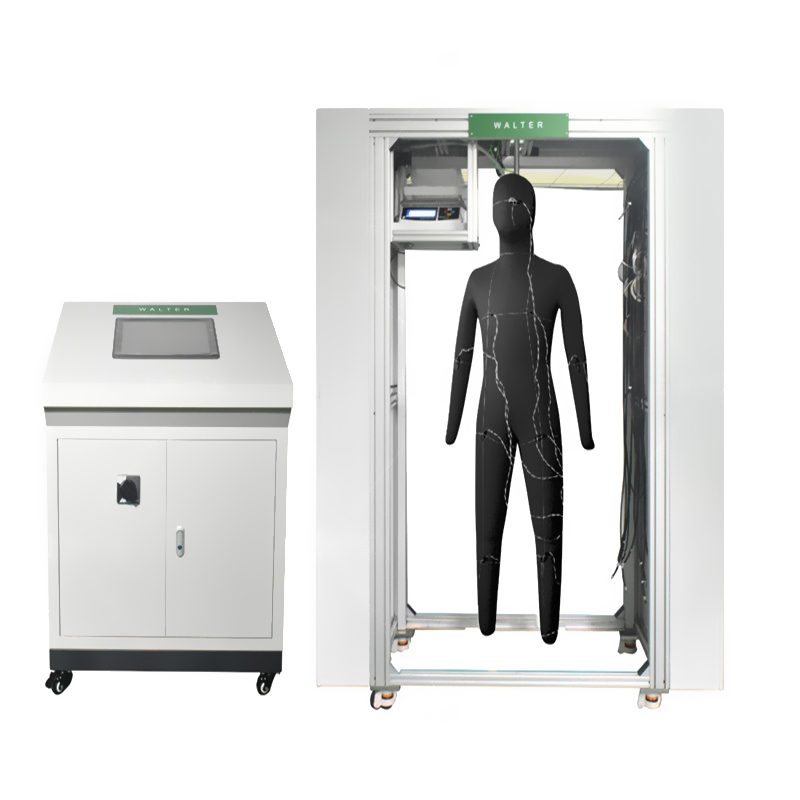

The tester consists of a mainframe, transmission mechanism, supporting plate, eight rubber-sealed metal clamps, and an electrical control system. The motor drives the supporting plate to rotate at 300 rpm, generating an eccentric motion (e=22.5mm) to cause each sample to move in a circular path of **45mm diameter**. The abrasive material then grinds the glazed surface of the sample. The electrical control system automates the test by presetting the number of rotations; it stops automatically upon reaching the target value.

Key Features:

Innovative design, smooth operation, low noise, and user-friendly interface.

Simultaneous testing of up to 8 samples (or fewer)。

Equipped with a digital timer relay; requires no manual monitoring after power-on.

Included Accessories:

One LM test mainframe.

One set of steel balls (abrasive)。

One kg of F80 white corundum powder.

Observation box (optional; additional cost required)。

Observation Box

I. Purpose

The observation box is used in conjunction with the M-type glazed tile wear tester to visually inspect the wear patterns on ceramic tiles after testing. It complies with the requirements for observation devices in standards:

ISO/DIS 10545-7-1996 (Ceramic Tiles – Surface Wear Resistance Test Method for Glazed Tiles)。

GB/T 3810.7-2006 & GB/T 3810.7-2016 (Test Method for Glaze Wear Resistance of Ceramic Tiles)。

II. Main Technical Specifications

Voltage: 220V, Power: 200 W.

Lighting:

Two fluorescent lamps with 6000–6500K color temperature.

Illuminance: ——300 lx on the tile surface (light source perpendicular to the sample)。

Box Dimensions: 610×610×610mm.

Interior Finish: Painted in natural gray.

Usage Note: Avoid direct light exposure during observation.

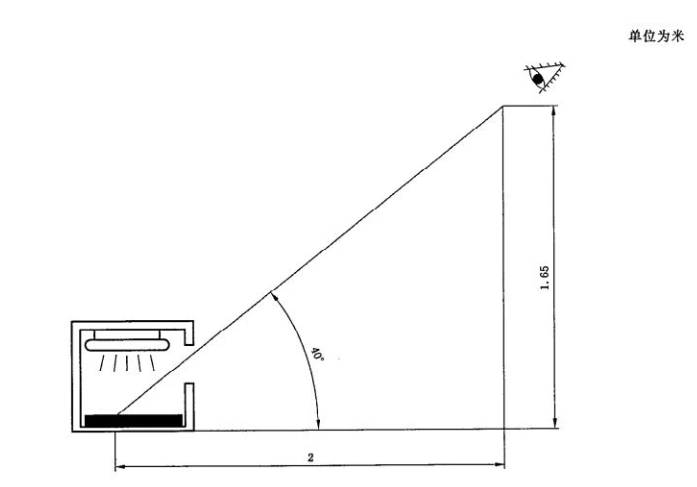

III. Schematic Diagram

Leave Message Get Price