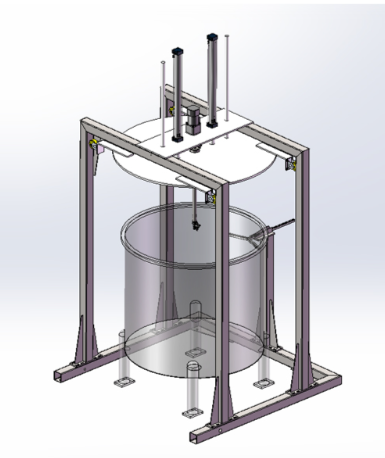

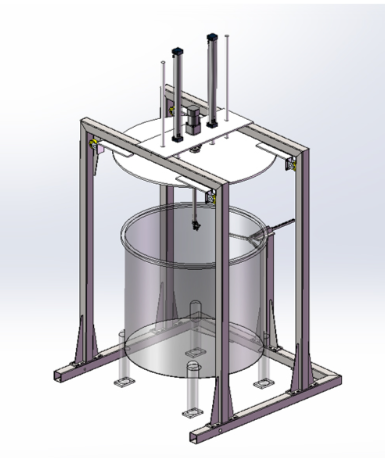

Mobile reactor cleaning machine

Stainless Steel Industrial Cylinder Automatic Cleaning System (Also Known as Cylinder Auto-Cleaning System)

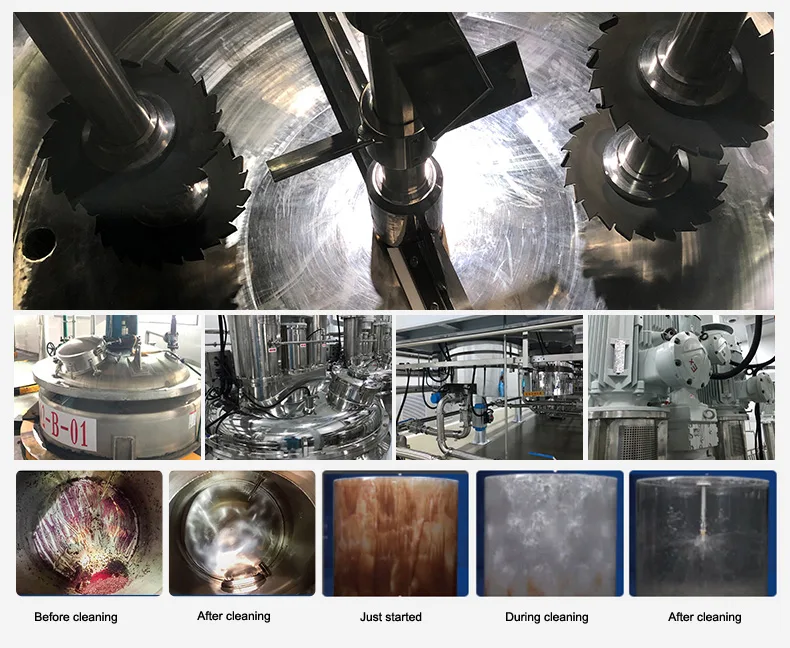

This system is designed for cleaning three-dimensional mixing tanks, mobile cylinders, transfer cylinders, and circulation cylinders. It utilizes high-pressure water jets controlled by an electric system to operate pumps, valves, and hydraulic mechanisms. The integrated rotating brush design combined with cleaning solution achieves three-dimensional, no-blind-spot coverage through cyclic cleaning. The system operates fully automatically with operator supervision for process monitoring and assistance.

System Configuration

1. Three-dimensional cleaning high-pressure water pump rated 20-500 kg/cm²

2. Copper brush cleaning with solvent spray

3. Inclined discharge structure

4. Blowdown port cleaning device

5. Explosion-proof configuration

6. Automatic lifting mechanism

7. Fixed external frame with safety guardrails

Mobile Cylinder Cleaning Equipment Workflow

1. Transport cylinders to inner cleaning station via forklift and position securely.

2. Cleaning head descends into drum via pneumatic cylinder with pressure detection (anti-damage mechanism), initiating pump station for 360° high-pressure internal cleaning. Fully automated process with no manual intervention.

3. MD high-pressure cleaner used for internal cleaning.

4. 2-4 minute cleaning cycle: Cleaning head stops rotation/spraying and retracts to standby position after completion.

Industrial Cylinder Cleaning Line Workflow

1. Manual loading into loading position with open end facing up (sensor detection).

2. 180° rotation transfer to transition conveyor via flipping mechanism.

3. Conveyor transports to DMF internal cleaning station: Doors close hydraulically, DMF pressurized by pump station forms high-pressure jet through rotating cleaner. Solvent recirculates to waste collection system.

4. Conveyor moves to fresh water cleaning station: Internal/external 360° high-pressure cleaning.

5. Transfer to drying station: Steam-heated airflow achieves 95% moisture removal.

6. Positioning at transition area.

7. Final 180° unloading flip via clamping mechanism.

8. Manual consolidation of cleaned cylinders.

Leave Message Get Price