Automatic Direct Residual Shear Machine

Introduction

· Automatic Digital Direct/Residual Shear Machine SHEARMATIC 300 is an ideal instrument to test the anti-shear ability of soil and other materials ( length up to 20mm). The instrument can shear mixed samples of 300mm2.

· The axial pressure to consolidate samples is provided by automatic programmable closed loop hydraulic system, and horizontal displacement is driven by a high resolution stepper motor. The instrument is completely controlled by microprocessor software. Motor controls axial pressure and displacement. Closed loop system controls the vertical hydraulic system and test procedure. The user interface is a ten-key scratch-resistant keyboard with a large-scale monochrome graphic display.

· SHEARMATIC 300 is an unique instrument with test parameters (horizontal and vertical load, and displacement) directly displayed on the monitor and stored in memory according to the default mode of record. The PC is only a port to download the test data. When test finishes, data can be downloaded via RS 232. these data can be processed via 30-WF6016/T2 and 30-WF6016/T9 Geo-Analysis or direct and residual shear forceGeo-Analysis module.

· More representative shear strength values an be obtained by testing large specimens. In addition, the application of large shear box can indicates frictional angel among different specimens.

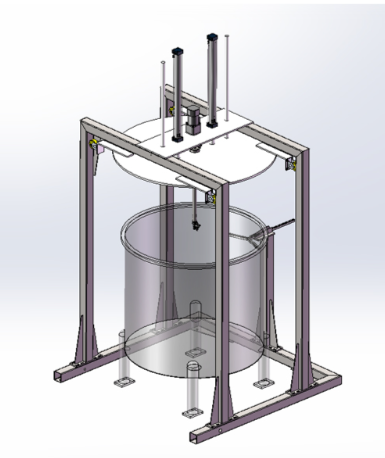

· SHEARMATIC 300 consist of a shear box, load cell of 100KN force, linear potentiometric sensors, and 10mm and 50mm stroke device with a fixation gantry.

Standards

ASTM D3080 Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions.

ASTM D6243 Standard Test Method for Determining the Internal and Interface Shear Strength of Geosynthetic Clay Liner by the Direct Shear Method.

BS 1377:7 Methods of Test for Soils for Civil Engineering Purposes-Part 7: Shear Strength Tests (Total Stress).

EN ISO 12957 Geosynthetics - Determination of friction characteristics - Part 1: Direct shear test

ASTM D5321 Standard Test Method for Determining the Shear Strength of Soil

Features

· Ideal instrument for testing shale, industrial waste slag, coarse brick and coal mine waste

· Specimen size up to 300mm2

· 100KN vertical pressure and horizontal force

· Variable speed: 0.00001-11.00000mm/min

· Automatic application of preset consolidation steps, up to 50.

· Automatic management of the test with the possibility to directly continue from consolidation to failure: the operator only needs to remove the clamping screws of shear box.

· Straight connection between shear box, drive unit and load cell for the axial transmission of the horizontal force along the shearing plane.

· Easy and immediate set up of the parameters via the large digital graphic display.

· Possible to set different speeds and travel (forward and reverse) in the residual shear tests.

· Each single step of axial force can be applied instantaneously or by means of a linear ramp in a preset time interval.

· Different and independent data recording method

· Real-time data acquisition software.

Technical Parameters

· Automatic Digital Direct/Residual Shear Machine SHEARMATIC 300 is an ideal instrument to test the anti-shear ability of soil and other materials ( length up to 20mm). The instrument can shear mixed samples of 300mm2.

· The axial pressure to consolidate samples is provided by automatic programmable closed loop hydraulic system, and horizontal displacement is driven by a high resolution stepper motor. The instrument is completely controlled by microprocessor software. Motor controls axial pressure and displacement. Closed loop system controls the vertical hydraulic system and test procedure. The user interface is a ten-key scratch-resistant keyboard with a large-scale monochrome graphic display.

· SHEARMATIC 300 is an unique instrument with test parameters (horizontal and vertical load, and displacement) directly displayed on the monitor and stored in memory according to the default mode of record. The PC is only a port to download the test data. When test finishes, data can be downloaded via RS 232. these data can be processed via 30-WF6016/T2 and 30-WF6016/T9 Geo-Analysis or direct and residual shear forceGeo-Analysis module.

· More representative shear strength values an be obtained by testing large specimens. In addition, the application of large shear box can indicates frictional angel among different specimens.

· SHEARMATIC 300 consist of a shear box, load cell of 100KN force, linear potentiometric sensors, and 10mm and 50mm stroke device with a fixation gantry.

Standards

ASTM D3080 Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions.

ASTM D6243 Standard Test Method for Determining the Internal and Interface Shear Strength of Geosynthetic Clay Liner by the Direct Shear Method.

BS 1377:7 Methods of Test for Soils for Civil Engineering Purposes-Part 7: Shear Strength Tests (Total Stress).

EN ISO 12957 Geosynthetics - Determination of friction characteristics - Part 1: Direct shear test

ASTM D5321 Standard Test Method for Determining the Shear Strength of Soil

Features

· Ideal instrument for testing shale, industrial waste slag, coarse brick and coal mine waste

· Specimen size up to 300mm2

· 100KN vertical pressure and horizontal force

· Variable speed: 0.00001-11.00000mm/min

· Automatic application of preset consolidation steps, up to 50.

· Automatic management of the test with the possibility to directly continue from consolidation to failure: the operator only needs to remove the clamping screws of shear box.

· Straight connection between shear box, drive unit and load cell for the axial transmission of the horizontal force along the shearing plane.

· Easy and immediate set up of the parameters via the large digital graphic display.

· Possible to set different speeds and travel (forward and reverse) in the residual shear tests.

· Each single step of axial force can be applied instantaneously or by means of a linear ramp in a preset time interval.

· Different and independent data recording method

· Real-time data acquisition software.

Technical Parameters

| Items | Parameters |

| Sample size | Max.300mm2 |

| Shear force | 100KN |

| Speed range | 0.00001-11.00000mm/min |

| Maximum stroke | 75mm |

| Consolidation steps | Up to 50 steps |

| Data acquisition | RS 232 port and direct and residual shear force Geo-Analysis module |

| Power | 2000w |

| Dimension | 1470 x 758 x 1570 mm(W x D x H) |

| Weight | 800kg |

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price