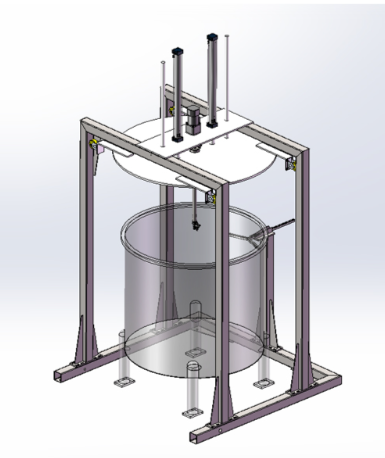

Cleanliness tester

Product Introduction:

Cleanliness tester is mainly used for cleanliness detection and analysis of auto parts and new energy power battery parts, which can automatically count and analyze the type, size and quantity of impurity particles on the filter membrane, and classify them according to size grade. It can meet the requirements of VDA19, ISO16232, ISO4406, Volkswagen, BMW, Ford, Mercedes-Benz, GM and other powertrain factories for parts cleanliness testing specifications, and issue standard data reports in line with the above specifications, and have the ability to customize data reports.

Features:

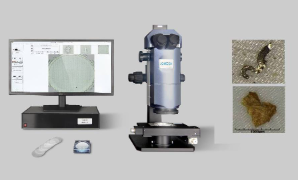

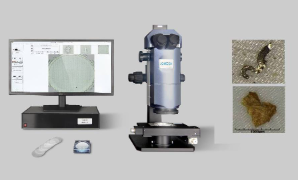

1. The system can automatically identify and determine three types of impurities: metal particles, non-metal particles, fibers.

2. It can automatically calculate the number of metal particles and non-metal particles, classify and determine the grade according to ISO16232 according to the length grade, and calculate the total length of the fiber on the filter membrane.

3. The system can also automatically measure and calculate the length, width and other dimensions of a single particle.

4. With the hardware support function that can accurately distinguish metal and non-metal particles by automatically adjusting polarized light, it can distinguish metal and non-metal particles correctly so that there is a standard data basis for judgment.

5. Measurement software interface and user manual in Chinese, English and German.

6. The software can automatically splice scanned images and store the scanned images of the entire filter membrane; The stored filter images can be accessed at any time for re-analysis, storage and automatic export of reports, and the particle level in the report template can be set according to user needs. The scan results can be manually modified and can be segmented or correlated with particles of any shape.

7. Equipped with free travel high-precision automatic scanning stage, automatic manual control in two ways. Finally, the standard block is used to control the overall accuracy and detection results of the scanning table and equipment.

8. Equipped with calibrated microscope standard block (with calibration certificate) and camera scale calibration block, and provide spare parts in the later technical support as a spare for the calibration cycle, the recommended calibration cycle of the standard block is once every two years.

9. Equipped with a special bracket for the filter membrane, the filter membrane can be scanned directly without repositioning, and can be applied to 25mm, 47mm, 50mm and other filter paper specifications.

10. The scanning data of nylon mesh braided film is the same as the scanning data of surface filter film, and the results are not affected by the grid.

Leave Message Get Price