Current sensor

Product Introduction:

CTS designs alternating current (AC) and direct current (DC) sensors for industrial and automotive applications such as electric vehicles (EVs), hybrid electric vehicles (HEVs), battery electric vehicles (BEVs), and plug-in hybrid electric vehicles (PHEVs) using Hall effect technology. Current sensors allow us to measure the power used by various components, such as motors, which are essential in optimizing motor performance and metrology applications. Our current sensors track DC and AC currents up to 10kHz with high accuracy and low phase shift.

Advantages:

Certified lead free

Low hysteresis

High linearity

Flexible installation options

Dc and AC compatible

Hall-sensor measurement

Undisturbed sensing

Wide current range available from 25 to 2000 A

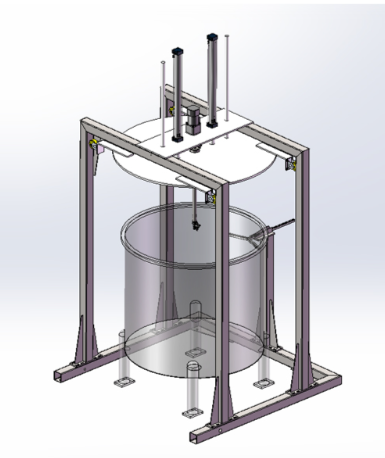

1. Install a current sensor on the bus

These sensors range from 250-1500 A and can be mounted directly on the bus. Various customization options are available, such as calibration and analog output ranges. Our engineers can work with your team to create sensors that fit the limitations of your application. This range of sensing solutions can be accurate to 1%.

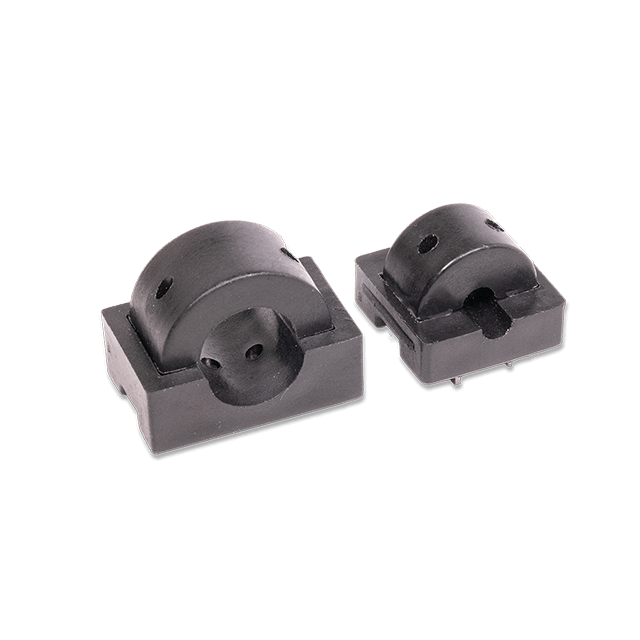

2. Install the current sensor on the PCB

These AC products range from 200-1000 A and can be mounted directly on the board or in stand-alone mounting packages. A variety of standard current ranges as well as custom specific calibrations are available. Our engineers can work with your team to create sensors that fit your exact application limitations. This range of sensing solutions can be accurate to 1%.

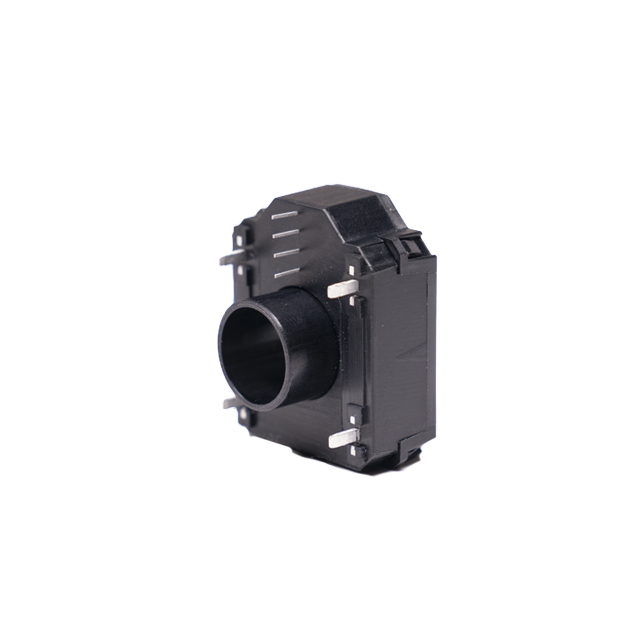

3. Clamp the current sensor

Our magnetic field concentrators are designed for non-invasive and isolated measurement of currents up to 200A. Thanks to their clamping design, these non-contact current sensors can be installed safely without interrupting or cutting the cable. They consist of soft ferromagnetic shields with superior material properties such as high linearity and extremely low hysteresis.

4. Critical sensing systems

Monitoring multiple parameters ensures safe and durable operation in highly complex applications. Our advanced sensing modules are specifically designed to handle these complex systems and provide superior capabilities to accurately measure critical parameters. These electrical isolation systems have a range of supports, such as optimizing battery charging, improving battery life, promoting high battery capacity, and collectively improving performance.

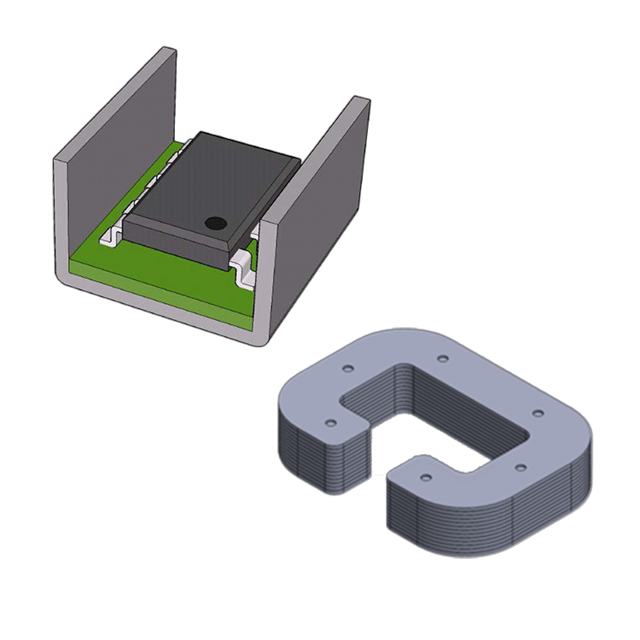

5. Core and guard

The two most important components of a current sensor are the magnetic core and shielding, which are used to concentrate magnetic flux and protect the sensor from external magnetic fields. CTS is available in a variety of sizes and materials as well as additional features to make installation easy.

Leave Message Get Price