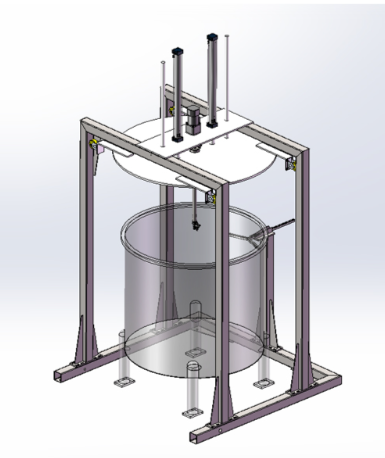

1000 tons wear resistance tester

Device description:

The at1000 wear tester has been used around the world since 1970 and is ideal for comparison and quality control of platelet-shaped fillers and pigments. When these fillers and pigments are used, the unit provides information on the wear properties of paper machine screens, cutting and stamping tools, as well as roller conveyors and blades. The at1000 wear testing machine has been in production since 1970 and its functional principle has remained the same. However, the device has been improved every once in a while in terms of handling, test accuracy and long-term accuracy. All the experience gathered since its launch has been integrated into the design of the original Einlehner AT 1000, the latest model from PTE Austria. The device is equipped with an integrated touch screen for intuitive and easy operation. The rotary mill rotates at a standard speed of 1450 RPM or 1800 RPM independent of the main frequency (50-60 Hz)。 In addition, the new electronic system can be used to select any other rotation value. The preset and actual revolutions (up to 999.990 revolutions) are displayed on the touch screen, and the speed of the grinding mixer can be controlled. The bottom of the mixing rod is narrower because it is submerged in the suspension. This keeps the top deflector free from contamination.

Features:

Quality materials and manufacturing

Special technology since 1970

The touch screen operation is intuitive and convenient

Special tools for simple PVC ring installations

An 11 measuring cup

1 starter kit, 500 screens, 200 PVC rings and 25 stainless steel wear plates

Applicable standards:

Zellcheming-Merkblatt V / 27.5/75

Leave Message Get Price