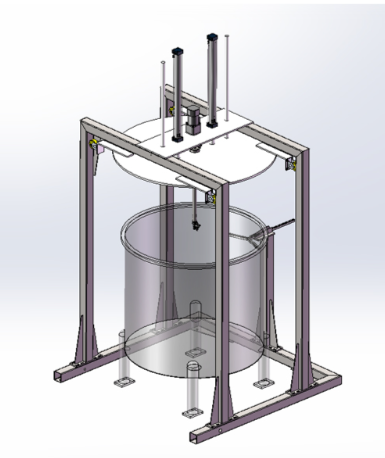

Powder compaction density meter

Definition and use:

Powder uncompacted density meter is mainly based on the powder is not applied specific pressure, so that it is compacted in a certain volume, and then measure the density after compaction. It is widely used in material science, chemical, pharmaceutical, food and new energy batteries and other fields, used to evaluate the compaction performance of powder materials, to provide technical support for product development and quality improvement.

How it works:

The working principle of the powder uncompacted density meter involves mechanics and volume measurement. During the test, a certain amount of powder sample is placed in a special mold, and a stable and accurately controlled pressure is applied to the powder through a pressure device. Under the action of pressure, the space between the powder particles gradually decreases, and the powder is not compacted. At the same time, the tester measures the volume change of the powder, which is usually achieved with the help of a high-precision displacement sensor. Combining the initial mass of the powder, the compaction density of the powder can be obtained by density calculation formula.

Main features:

High-precision measurement: The powder uncompacted density meter uses high-performance sensors and control systems to achieve high-precision measurement of the powder uncompacted density.

Pressure control: The instrument has precise pressure control function, and the user can adjust the pressure according to the need to simulate different use environments.

High degree of automation: Modern powder uncompactified density meters are usually equipped with automated control systems and data acquisition systems, which can automatically complete the measurement process and save data.

Easy to operate: the operation interface of the instrument is simple and clear, and the user is easy to operate and maintain.

Technical parameters:

The technical parameters of a powder uncompacted density meter may vary by brand and model, but usually include the following:

Measuring range: refers to the range of powder uncompacted density that the instrument can measure.

Pressure range: The range of pressure that the instrument can apply.

Accuracy: refers to the accuracy of the instrument measurement.

Resolution: The smallest measurement that an instrument can distinguish.

Measurement speed: refers to the time required for the instrument to complete a measurement.

Leave Message Get Price