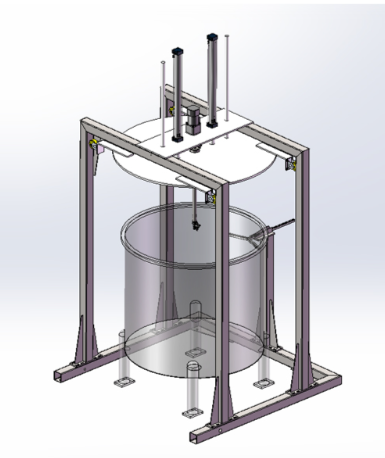

Anti-crack fatigue tester

How it works:

By simulating the cyclic loading stress that the material may be subjected to during actual use, such as tensile, compression, bending, etc., the anti-crack fatigue tester tests the fatigue properties of the sample containing cracks. By observing the occurrence and development of fatigue cracks during cyclic loading, the anti-crack fatigue performance of the material can be evaluated.

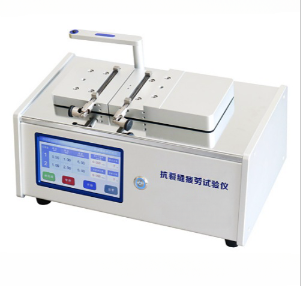

Technical parameters:

The technical parameters of the anti-crack fatigue tester may vary from model to model, but usually include the following aspects:

Maximum moving distance: generally 10mm(adjustable), indicating the maximum distance that the testing machine can move in a single cycle.

Moving distance accuracy: usually 0.01mm, indicating the accuracy of the testing machine in the moving process.

Operating speed: adjustable in the range of 0.01mm/min to 20mm/min, used to control the moving speed of the tester

Tensile measurement range: generally 10N to 250N(the specific range may vary by model), used to measure the force of the specimen during the tensile process.

Test plate size: The common test plate size is 120mmx80mmx10mm or 120mmx40mmx10mm(the specific size may vary by model)。

The power of the whole machine: generally about 80W (the specific power may vary by model)。

Instrument size and weight: The exact size and weight may vary by model and manufacturer, but are generally compact and easy to operate.

Functional features:

High precision measurement: The accuracy of the test results can be ensured through the high precision moving distance and tension measurement system.

Adjustable parameters: The maximum moving distance, running speed and other parameters can be adjusted according to actual needs to meet the test needs of different materials.

Automatic control: The use of advanced control system can realize the automatic control of the test process and improve the test efficiency.

Data recording and analysis: The testing machine is usually equipped with a data recording and analysis system, which can record and analyze the test data in real time, providing strong support for material development and quality control.

Leave Message Get Price