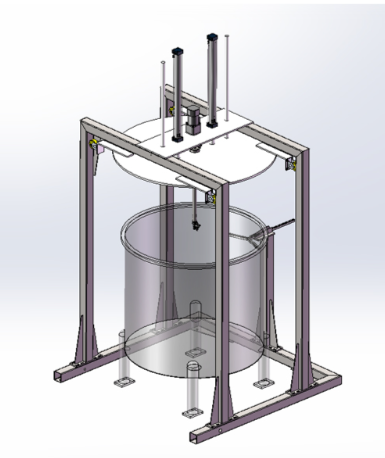

Shock absorbing buffer testing machine

Main uses:

Evaluation of shock absorption and cushioning performance: The shock absorption and cushioning testing machine can simulate the shock and vibration environment in actual use, and test the shock absorption and cushioning performance of materials or products. This helps to understand the response characteristics of a material or product when subjected to shock or vibration, thus assessing its stability and reliability in practical applications.

Optimization of product design and production process: Through the test of shock absorber, it can provide data support for the optimization of product design and production process. For example, in the fields of automotive parts, aerospace equipment, electronic products, etc., the device can be used to evaluate the impact of different materials, structures or processes on the shock absorption performance of products, so as to guide the improvement of product design and production processes.

Quality control and inspection: The shock absorber can also be used for quality control and inspection. During the production process, the equipment can be used to check whether the product meets the preset performance requirements of the shock absorption buffer, thus ensuring the consistency and stability of the product quality.

Applicable standards:

During the testing process, the shock absorber needs to follow a series of standards and specifications to ensure the accuracy and comparability of the test results. Here are some of the main applicable standards:

Related industry standards:

The test method, test conditions and result evaluation of the testing machine in the buffer usually need to follow the relevant industry standards. For example, in the automotive industry, it may be necessary to follow industry standards related to the heUI buffer performance of automotive components for testing.

International Organization for Standardization (ISO) standards:

1SO has developed a series of international standards on material testing, product performance testing, etc., and the shock absorber may need to follow some 1SO standards during the test process to ensure the international comparability and recognition of the test results.

National standard (GB/T):

In China, the test methods and requirements of shock absorption and buffer testing machines usually need to follow the relevant provisions of the national standard (GB/T)。 These standards specify the requirements of test equipment, sample preparation, test conditions, and result evaluation in detail to ensure the accuracy and consistency of test results.

Enterprise standard:

In addition to the above standards, some enterprises may also develop corporate standards according to their own needs and actual conditions. These enterprise standards may be more specific and detailed to meet specific product or test requirements.

It should be noted that due to the reduction of Heui, the application field of the testing machine is wide, and the specific applicable standards may vary depending on the industry, product, test requirements and other factors. Therefore, when using the HeUI slow and medium testing machine for testing, the relevant standards and specifications should be carefully consulted to ensure the accuracy and comparability of the test results.

Leave Message Get Price