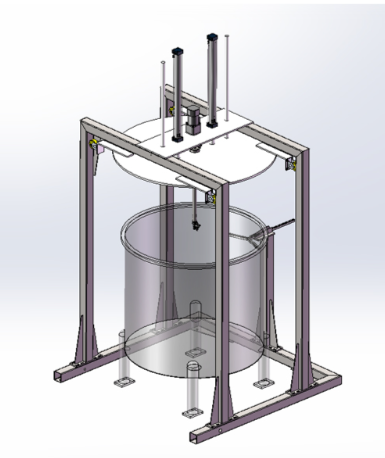

Large diameter blasting test machine

Main uses:

1. Test the pressure resistance of the pipe:

The large diameter blasting test machine can evaluate its pressure resistance by gradually increasing the pressure inside the pipe to test its tolerance under increasing pressure. This is essential to ensure the safe use of tubing in high-pressure environments.

2. Test blasting performance of pipe:

The equipment can simulate the impact, vibration and other conditions that the pipe may encounter in actual operation, and carry out blasting test on the pipe to check its blasting performance. This helps predict pipe performance under extreme conditions and provides a basis for pipe design and maintenance.

3. Detect pipe defects:

Through the blasting test, the performance of the pipe in the cracking process can be observed, so as to find and determine the defects of the pipe, such as internal bubbles, inclusions, cracks, brittleness of the material, poor welding and other problems. This is of great significance for improving the quality and safety of pipes.

4. Screening of unqualified pipes:

Through blasting test, unqualified pipes can be screened out to avoid production interruption and loss caused by quality problems. This helps improve production efficiency and product quality,

5. Research and Teaching:

Large diameter blasting machines can also be used in research and teaching fields, providing an experimental platform for researchers and students to gain insight into the properties and behavior of pipes.

Applicable standards:

Large diameter blasting machines usually comply with or refer to the following series of international standards and specifications:

GB White T standards: such as GB/T6111-2003 "Thermoplastic pipe for fluid transport internal pressure test method" and GB/T15560-1995 "Fluid transport plastic pipe hydraulic instantaneous blasting and pressure test method", these standards specify the pipe pressure and blasting performance test methods and requirements.

ISO standards: such as IS0 6802 and IS0 6803, these standards cover wire reinforced rubber and plastic hoses and hose parts flexural hydraulic pulse test and non-flexural hydraulic pulse test. Although these standards are mainly for hoses, they can also provide a certain reference for large diameter blasting tests.

Leave Message Get Price