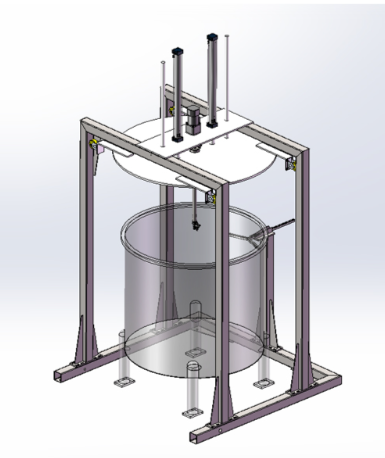

Creep testing machine with full incision

Main use:

Evaluate the creep properties of materials:

The full notch creep testing machine can simulate the stress conditions of the material in actual use, and evaluate the creep performance of the material by continuous loading and observing the creep deformation of the material in a specific temperature, solution and other environment. This is of great significance for understanding the long-term stability and service life of the material.

1. Material development and optimization:

During the material development phase, the device can be used to screen and optimize material formulations to improve their variable properties. At the same time, in the process of material optimization, the full notch variable testing machine can be used to detect the influence of different materials, structures or processes on creep properties, so as to guide the improvement of material design and production process.

2. Quality control and inspection:

In the production process, the full notch variable testing machine can be used to test whether the product meets the preset variable performance requirements. This helps to ensure consistency and stability of product quality, reducing returns and repair costs due to quality problems.

3. Product design and production support:

Through the testing of the creep testing machine, it can provide reliable data support for product design and production. For example, in the fields of pipes, welded joints, etc., the equipment can be used to evaluate the influence of different materials, wall thickness, structure and other factors on creep properties, so as to guide the improvement of product design and production process.

Applicable standards:

The creep testing machine needs to follow a series of standards and specifications during the testing process to ensure the accuracy and comparability of test results. Here are some of the main applicable standards:

S0 16770-2004/GB/T 32682-20106:

These two standards were developed by the International Organization for Standardization and the Standardization Administration of China respectively to determine the environmental stress fracture (ESC) performance of plastics (especially polyethylene), of which the full notch creep test is an important part.

ASTM F1473-2013:

This standard was developed by the American Society for Materials and Testing (ASTM) to measure the notch tensile test of polyethylene pipes and resins against slow crack growth. Full notch creep testing machines can be used to evaluate the slow crack propagation properties of materials under this standard.

GB/T 11546.1/IS0 899-1:

These two standards were developed by the Standardization Administration of China and the International Organization for Standardization to determine the variable properties of plastics. Among them, the full notch creep testing machine can be used for tensile medium change tests to evaluate the creep deformation and fracture time of materials.

Other relevant standards:

Such as ASTM D2290, 1S0 16241-2005, GB/T15820-1995/1S0 3501, etc., are also suitable for the test of full-cut creep testing machines. These standards may specify specific test methods and requirements for different types of materials, products or test requirements.

Leave Message Get Price