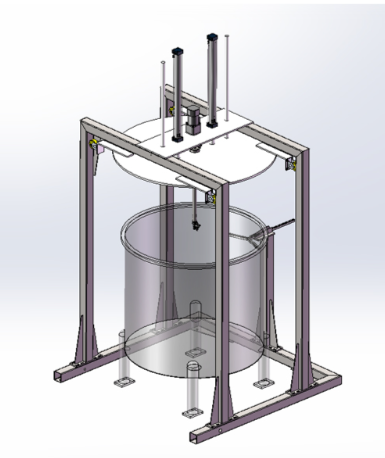

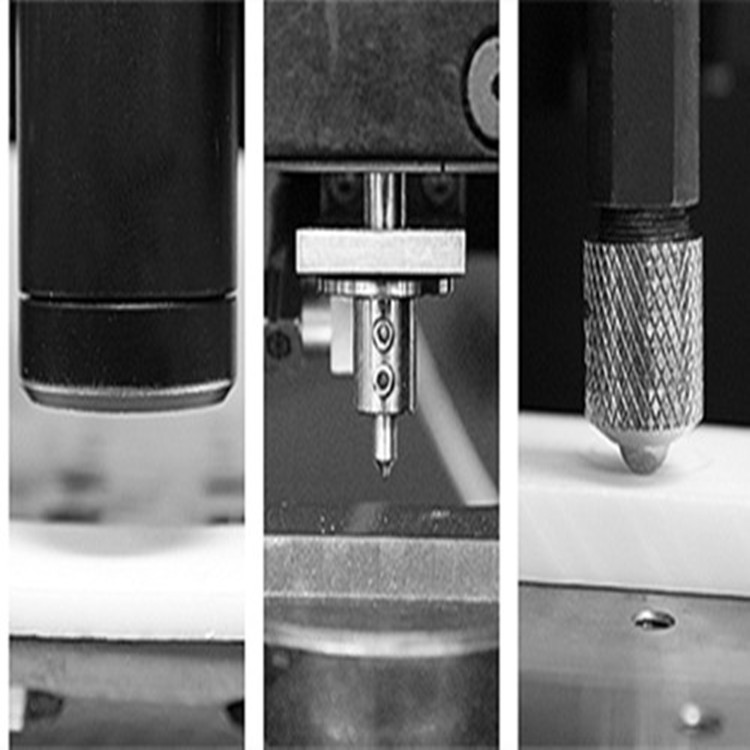

KK03 Scratch tester

Product Introduction:

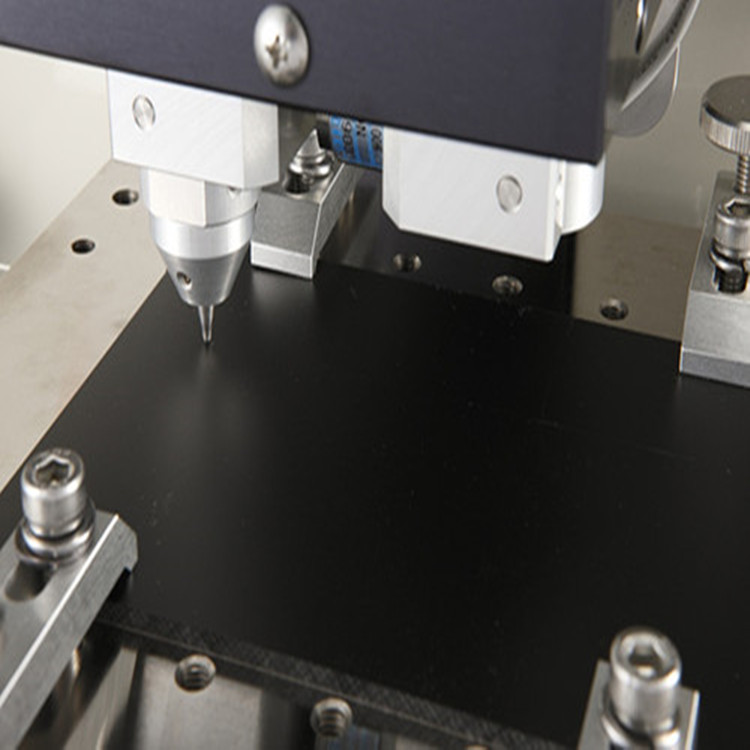

With the continuous expansion of the use of plastic molding products, from the point of view of the surface appearance of molded products (creativity), improving scratch resistance (scratch characteristics) has become an important topic. And scratch resistance is also very important from the point of view that scars formed on the surface of the molded product may reduce the strength of the product. Scratch testing is performed by horizontal movement of the scratch needle against the pattern. Scratch characteristics were previously evaluated by a "constant vertical load test", but the American Society for Materials and Testing (ASTM) and the International Organization for Standardization (ISO) standardized the "vertical load test" (ASTM D7027-05/S019252)。

Scope of application:

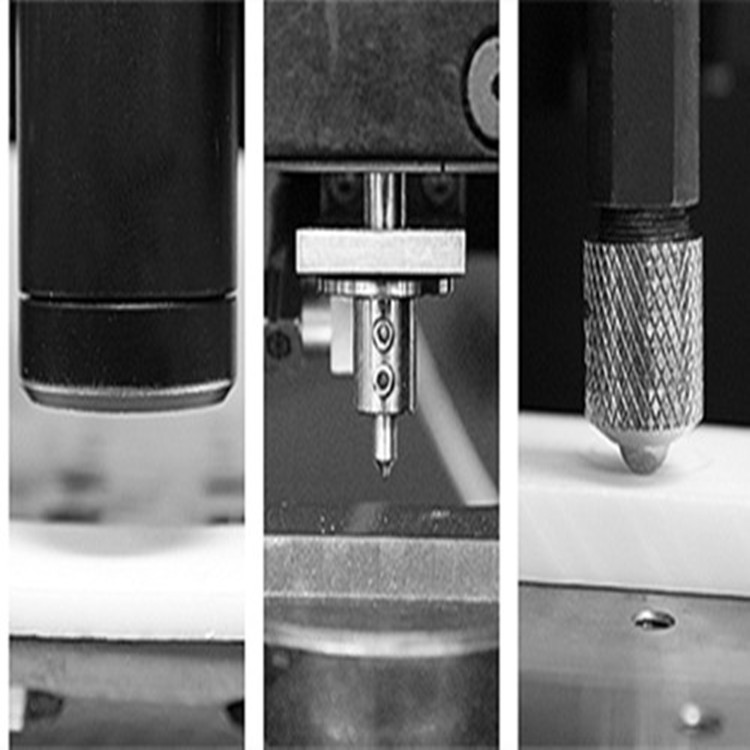

The tester uses a steel needle to scratch films, plastics, automotive interior and exterior decorative materials, coating materials, etc., to evaluate the material's "scratch resistance" (scratch characteristics)。

Features of scratch tester:

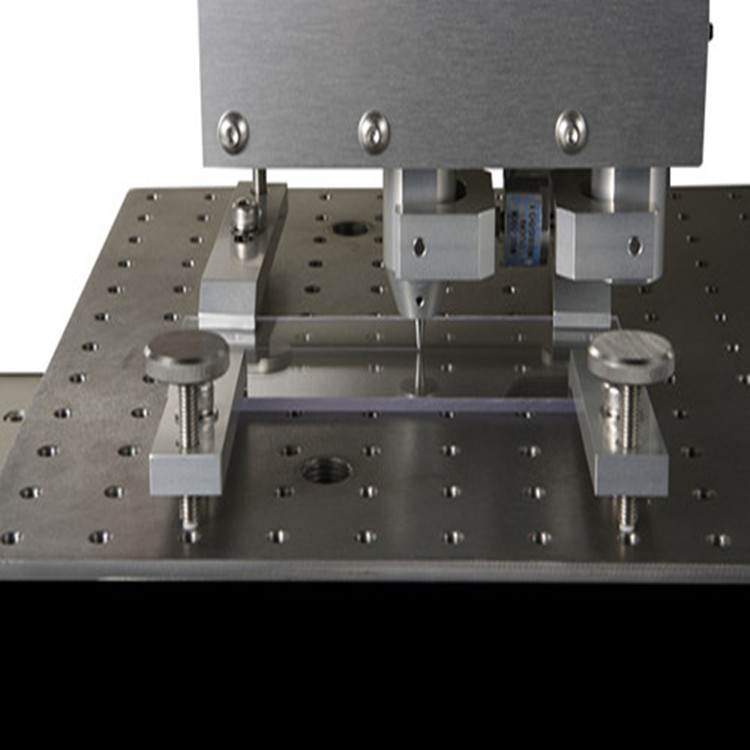

1. Teaching function

Use this function to set the load zone with high precision before sampling.

2. Easy to operate with touch screen

All functions can be used and configured through the touch screen installed in front of the Settings.

3, the surface has a bump can also test scratches

The Yaru drive for vertical loads uses a county frame mechanism, so that even the surface with a concave and convex pattern can be tested without affecting the linear increase in load characteristics.

4. Memorizable test conditions

Storage capacity up to 20, capable of memorizing test conditions.

Technical parameters:

The KK-03 is fully compliant with I50 and ASTM international standards

Size :W545*D455*H680(mm)

Weight: About 150KG

Test mode: Load increase mode

Speed range :1——200 mm/sec

Load control range :0.1——5.00N

Horizontal (x) load test range :5N

Leave Message Get Price