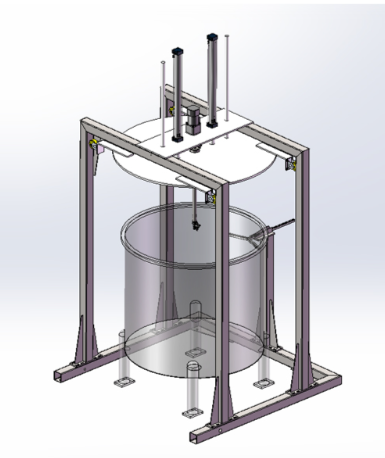

Steel wheel wear testing machine

Product Introduction:

The cycloidal pinwheel reducer has the advantages of large reduction ratio, compact structure, smooth transmission and adjustable abrasive flow rate, which can effectively save the amount of abrasive. The testing machine through the gear drive deceleration to steel wheel speed 75r/min, gear drive compared with the belt drive deceleration, smooth, no skid phenomenon, steel wheel rotation by the time relay control, the motor to the predetermined time is also transferred to the test requirements of the speed

The motor stops automatically. The testing machine has the characteristics of reasonable design, simple structure, beautiful appearance, easy operation, smooth rotation, automatic shutdown to meet the test requirements, etc., which is mainly suitable for wear resistance test of cement bricks.

Technical parameters:

Grinding wheel -: Diameter 200+0.2mm, thickness 10+0.1mm,

Grinding wheel 2: Diameter 200+0.2mm, thickness 70+0.1mm, hardness HB203-245

Grinding wheel speed :75+4r/min constant;

Sample size :100mm x 110mm;

Abrasive: Size is IS08486-1986 F80 white melt alumina:

Abrasive feed speed :(100+10)g/100r adjustable flow rate;

Hopper volume: greater than 5L:

Test time: preset, digital display;

Weight -: a mass of 2.5kg(for GB/T3810.7-2006)

Weight two: a mass of 14k(for GB/T12988-91)。

Overall dimensions :6000x580x130mm

Weight: About 150kg

Meet the standard:

GB/T3810.7-2016 "Wear resistance test method for unglazed brick"

ISO/DIS10545/6-94 "Unglazed brick resistance to deep wear test method"

GB/T12988-1009 "Inorganic floor material resistance test method"

Leave Message Get Price