The working principle of the cleanliness tester

The working principle of the cleanliness tester varies depending on the type and application scenario, but the core goal is to quantitatively or qualitatively assess the degree of contamination on the surface of an object. Here's a step-by-step explanation of how it commonly works:

1. Sampling and pretreatment

Contact sampling: Collect contaminants (such as particles, oils, chemical residues) on the surface under test by wiping, rinsing, or vacuum adsorption.

Non-contact sampling: The use of air flow, laser or electromagnetic wave indirect access to pollutant information, to avoid secondary pollution.

2. Detection technology classification and principle

a. Optical detection method

Principle: The light source (such as laser, LED) irradiates the tested surface to analyze the intensity or spectral changes of the reflected/transmitted light.

Particle detection: Laser scattering method to measure particle size and quantity (such as ISO 16232 standard)。

Oil/liquid residues: UV light stimulated fluorescence reaction to detect hydrocarbon contaminants.

Application: metal workpiece, electronic components surface cleanliness test.

b. Chemical analysis

Principle: Pollutants are extracted by solvent, and components are detected by chemical reaction or instrumental analysis (such as infrared spectroscopy, colorimetry)。

Ion contamination test: Resistivity measurement or ion chromatography (IC) analysis of electrolyte residues.

Organic residue test: Quantitative analysis by gas chromatography-mass spectrometry (GC-MS)。

Application: Cleaning verification of semiconductor and medical equipment.

c. Physical measurement methods

Weighing method: Use a precision balance to weigh the quality difference before and after cleaning to assess the total amount of contaminants (e.g. ISO 4406 hydraulic oil cleanliness)。

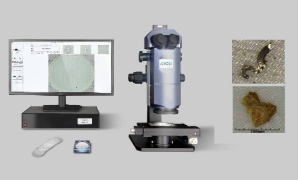

Particle counting method: Microscopes or automatic particle counters count the number of particles per unit area (such as automobile engine parts inspection)。

Membrane filtration: The pollutants are trapped on the filter membrane and analyzed by a microscope or sensor.

d. Microbiological detection method

Principle: Culture method or ATP bioluminescence method to detect microbial residues (such as medical equipment sterilization verification)。

Application: Cleanliness control in pharmaceutical and food industries.

3. Data processing and standardization

Quantitative indicators: Classification of pollution levels (e.g. particle size distribution, number of particles per unit area) according to standards (e.g. ISO 4406, NASA-STD-6001)。

Automated analysis: The software generates reports and compares the limits to determine whether the standards are met.

4. Typical application scenarios

Industrial manufacturing: Detecting cutting fluid residue after machining of mechanical parts.

Medical equipment: Verify the cleaning effect of endoscopes or surgical instruments.

Electronic semiconductors: Control of nanoscale particle contamination on wafer surfaces.

Environmental monitoring: Assessing the cleanliness of precision instruments such as optical lenses.

Sum up

Cleanliness testers use physical, chemical or optical means to convert contaminants into measurable signals (such as light intensity, mass, chemical concentration), combined with standard thresholds to assess cleanliness. The design needs to be optimized for specific pollutant types (particles, organics, microorganisms) and industry standards to ensure the accuracy and reliability of the results.

2025-03-20 10:23

- Related News

VP-TEST-5000: Transpiration Analyzer for Textiles

DPL-2000: Steady-State Thermal Conductivity Tester

HTC-3000: Thermal Conductivity Analyzer for Extreme Environments

Flammability Analyzer by Oxygen Index

TRACKING-8000: Electrical Insulation Tracking Analyzer

MELTINDEX-3000: Polymer Flow Rate Analyzer

Color Fastness Tester Resistant to Scrub

CHRYSLER-BEND-5000: Automotive Component Flexibility Analyzer