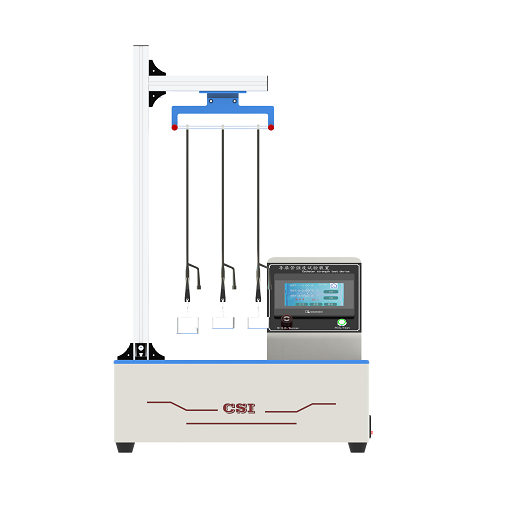

Catheter strength tester

Instrument Features

The equipment is an industrial-grade testing system for manufacturing quality control, featuring:

1. PLC-controlled automation with touch screen interface

2. Multi-language (Chinese/English) menu operation

3. Force transducer measurement system

4. Intelligent motion control mechanism

5. Built-in printer for instant test result documentation

6. Three-tier password security system

7. Standardized parameter settings including nominal capacity, probe displacement, printing configuration, test modes, calibration functions

8. Real-time display of test parameters: load value, sliding force (initial force, average force, maximum thrust)

9. Automatic failure detection with audible alarm

10. Test report generation including measurement data and pass/fail status

Test Principle

For balloon catheters:

1. Pre-treatment: Immerse in simulated urine for 14 days

2. Apply tensile force to the connection between tip and shaft

3. For side-hole catheters: Apply force specifically to the hole area

4. For non-side-hole catheters: Apply force between shaft and drainage cone interface

5. After loading, inspect for damage to the catheter assembly

- Test preparation:

- Pre-soak balloon-type catheters in simulated urine solution for 14 days

- Skip soaking step for non-balloon catheters - Force application:

- Apply specified tension to critical connection points

- Side-hole catheters: Focus force on hole reinforcement area

- Non-side-hole catheters: Apply load between drainage cone and main shaft - Post-test inspection:

- Visually inspect for cracks, detachment, or deformation

- Document damage degree according to ISO 5636-12 standard

Leave Message Get Price