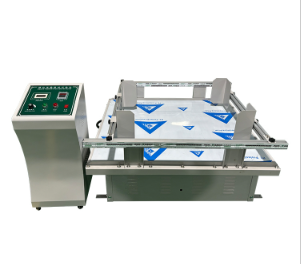

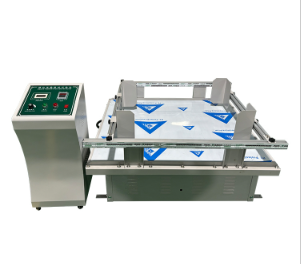

Simulate transport shaker

Main uses:

Simulation of transportation vibration environment: The simulation of transportation vibration table can simulate the vibration environment that may be encountered in cars, trains, ships and other transport vehicles, such as bumps, uphill, downhill, turning and other circumstances of the product collision, extrusion and other vibration, to evaluate the product in these conditions of transportation performance and packaging design rationality.

Evaluation of product vibration resistance: Through vibration testing, you can assess whether the product can withstand the test of the vibration environment during the transportation process, including structural vibration resistance, reliability and sound parts. This helps to ensure the safety and stability of the product during transportation.

Optimize product design and packaging: Test results from simulated transportation shakers can provide data support for product design and packaging optimization. For example, based on the test results, the product structure can be improved, the material strength can be enhanced, or the packaging design can be optimized to improve the transportation resistance of the product.

Quality control and inspection: During the production process, the simulated transport shaker can be used to check whether the product meets the preset vibration resistance requirements. This helps to ensure consistency and stability of product quality, reducing returns and repair costs due to quality problems.

R&d and Design support:

During the product development and design phase, the simulated transport shaker can be used to evaluate the impact of different materials, structures or processes on the vibration resistance of the product. This helps to guide the improvement of product design and production process, improve the overall performance of products and market competitiveness.

Applicable standards:

Simulation transport shakers need to follow a series of standards and specifications during testing to ensure the accuracy and comparability of test results. Here are some of the main applicable standards:

1S0 2247:

The transportation vibration test applicable to packaging and storage and transportation requires the necessary inspection of the tested item before the test, and the simulation of the specified vibration conditions during the transportation process to evaluate its durability in transit.

ASTM D4169:

The standards developed by the American Society for Materials and Testing include 11 different test sequences for various types and sizes of packaging and storage. Vibration and shock tests are carried out by simulating real transport conditions to evaluate the transport resistance of the product.

ISTA(International Transport Packaging Association) standards:

The packaging is divided into several categories according to its sensitivity to vibration and impact. In the process of testing, the environment and mode of transportation are required to be simulated, and the appearance, performance and other aspects of the test are inspected to evaluate the transportation performance of the product and the rationality of the packaging.

Other criteria:

Such as GB/T 4857.7-2005(China national standard), MIL-STD-810G Method 514.6(test standard issued by the United States Department of Defense), IEC60068-2-6(International Electrotechnical Commission standard), etc., are also suitable for the test of simulated transportation shaking table. These standards may specify specific test methods and requirements for different types of materials, products or test requirements.

Leave Message Get Price