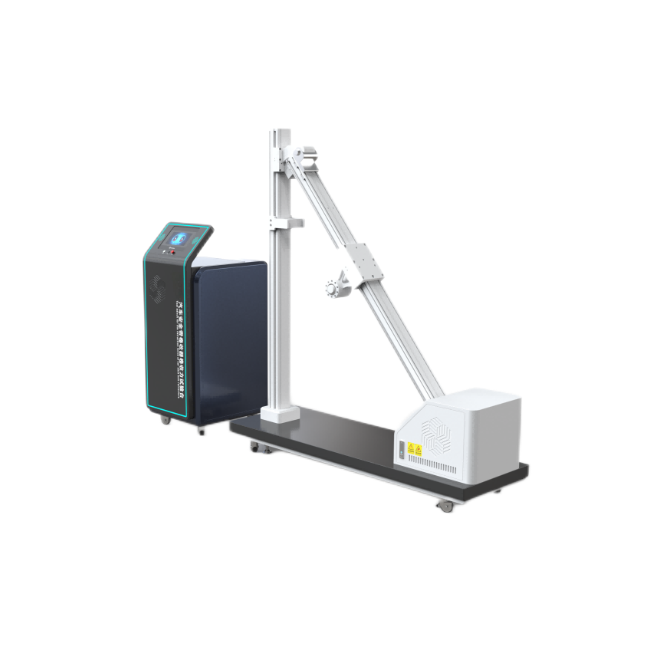

Automobile seat belt fixed point test bench

Applicable standards:

National mandatory standards:

GB 15083-2006 "Automobile seats, seat fixtures and headrests strength requirements and test methods"

GB 14167-2006/2013 "Car Seat Belt installation Fixed Point"

GB 11550-2009 "Automobile seat headrest strength requirements and test methods"

GB 13057-2003/2014 "Strength of passenger seats and their vehicle fasteners"

GB 14166-2013 "Seat belt, restraint system, Child restraint System for Motor Vehicle Occupants ISOFIX Child Restraint System"

International Standards and regulations:

Eu ECE R14 Uniform Regulation on the approval of Vehicles with regard to seat belt fixing Points

Eu ECE R17 Uniform Regulation on the approval of vehicles with regard to seats, seat fixation points and headrests

Eu ECE R80 (specific terms may vary from version to version)

FMVSS 207 Seating System

FMVSS 210 Seat Belt Assembly Fixing Point

FMVSS 225 Child Restraint System Fixed Point

Enterprise standard:

For example, the test requirements of the strength of the seat system and the strength of the seat belt fixing point in the EP development standard of the German Volkswagen company.

SAE J 384 Stationary Point Test Code for Seat Belts in Motor Vehicles

SAE J 385, Motor Vehicle Seat Belt fixed point performance requirements, etc.

Main parameters:

The main parameters of the car seat belt fixed point test bench may vary from model to model and manufacturer, but usually include the following aspects:

Load measuring range:

It is generally 030kN (multi-channel, such as 6 channels) or 015kN (less channel, such as 3 channels)。 This range can cover the strength test requirements of most car seat belt anchorage points.

Control accuracy:

For the force measurement control system of 0——30kN, when the measurement and control load is 5kN——30kN, the control accuracy is the standard value of ±200N; When the measurement and control load is 0——5kN, the control accuracy is the standard value ±100N.

For the 0-15kN force measurement control system, the control accuracy is similar, but the value is reduced.

Hydraulic cylinder number and load:

The number of hydraulic cylinders may vary depending on the design of the test stand, for example, a nine-channel test stand may be equipped with nine hydraulic cylinders.

The load capacity of each hydraulic cylinder also needs to meet the test requirements, such as the load capacity of 3T.

Travel and loading speed:

The stroke of the hydraulic cylinder is usually longer, such as 1000mm, to accommodate different sizes of seats and seat belt fixing points.

The loading speed can reach the pre-set output in a specified time, such as 2 seconds or less.

Loading force holding time:

The load force holding time can be adjusted according to the test requirements, such as 0.2s to 120s stepless.

Leave Message Get Price