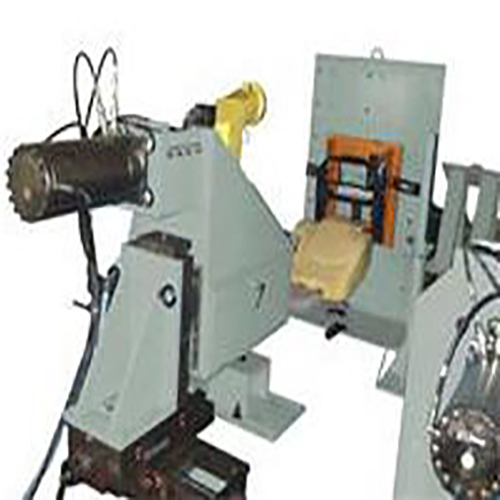

Car Seat Launching Headrest Impact Strength Evaluation System

Compliance Standards

- FMVSS 202a (Head Restraints)

- ECE R17 (Vehicle Seat Strength)

- ISO 17373 (Road vehicles - Head restraints)

- IIHS Head Restraint Rating Protocol

- Euro NCAP Whiplash Assessment

Technical Parameters

| Parameter | Specification |

|---|---|

| Impact Velocity | 5-24 km/h (1.4-6.7 m/s) |

| Max Impact Energy | 500J (±2%) |

| Acceleration Range | 0-100g (±1.5%) |

| Test Mass | 7kg/18kg/24.5kg (Selectable) |

| Measurement Frequency | 100kHz (16-bit DAQ) |

| Time Resolution | 10μs |

| Power Requirements | 3PH 480VAC 60Hz |

Key Features

- Pneumatic launch system with velocity control

- 3D high-speed impact analysis (100,000 fps)

- Biofidelic neck injury criteria calculation

- Automatic rebound prevention mechanism

- Crash pulse reconstruction capability

Test Capabilities

| Test Mode | Standard | Measurement Parameters |

|---|---|---|

| Static Energy Absorption | FMVSS 202a S5 | Force-Displacement Curve |

| Dynamic Whiplash Simulation | Euro NCAP | NIC, Nkm, T1 Acceleration |

| High-Speed Impact | IIHS | Head Travel Distance |

Measurement System

- Triaxial accelerometer array (±200g)

- Laser Doppler velocimeter

- Infrared thermal imaging (failure detection)

- 64-channel data acquisition system

Standard Configuration

- Electromagnetic launch track (3m length)

- BioRID II anthropomorphic test device

- Safety containment chamber

- CrashView Pro analysis software

Advanced Options

- Hybrid III 50th percentile dummy

- High-speed X-ray imaging

- Environmental simulation chamber (-40°C to +85°C)

- AR/VR impact visualization

Safety Systems

- Double interlock safety circuit

- Automatic mass arrestor system

- Blast-resistant observation window

- Emergency air purge system

Main parameters:

Impact speed: The impact speed of the tester is usually between 25 and 30km/h, which is a key parameter to simulate vehicle collision or deceleration. The specific speed value should be determined according to the test criteria and the type of seat.

Impact head type: Impact head type is a component that simulates the shape and quality of the passenger head, and its parameters such as diameter and equivalent mass should meet the requirements of relevant standards. The common impact head type has a diameter of 165mm and an equivalent mass of about 6.8kg.

Measurement accuracy: The measurement accuracy of the tester includes impact velocity measurement accuracy, acceleration measurement accuracy, etc. These precision parameters determine the accuracy and reliability of the test results. Generally speaking, the impact velocity measurement accuracy should be about ±1%, and the acceleration measurement accuracy should be about ±3%.

Adjustment range: The impact arm of the tester usually has a large adjustment range in the Z direction to adapt to different seat types and test needs. At the same time, the Angle of the impact arm can also be adjusted to simulate the collision situation at different angles.

Data acquisition and processing: The tester should be equipped with a high-speed data acquisition system, which can record various data in the test process in real time, such as impact speed, acceleration, deceleration, etc. At the same time, the data should be able to be subsequent processed and analyzed to produce accurate test results.

Safety protection: The tester should have perfect safety protection measures, such as safety protection net, emergency stop button, etc., to ensure the safety and reliability of the test process.

Leave Message Get Price